Chapter 6. Sample measurement

- 6.1. Using the PCI-1720 D/A card -- Exercise 1

- 6.2. Using the real-time clock with PCI 1720 D/A card – Exercise 2

- 6.3. Using the PCI-1784 Counter card -- Exercise 3

- 6.4. Open Loop Control measurement – Motion control/Exercise 4. Open-loop test

- 6.5. Closed Loop Control Measurements -- Exercise 5

-

- 6.5.1. Parameter tuning of the P controller -- Test 1.

- 6.5.2. Step signal response of the P controller -- Test 2.

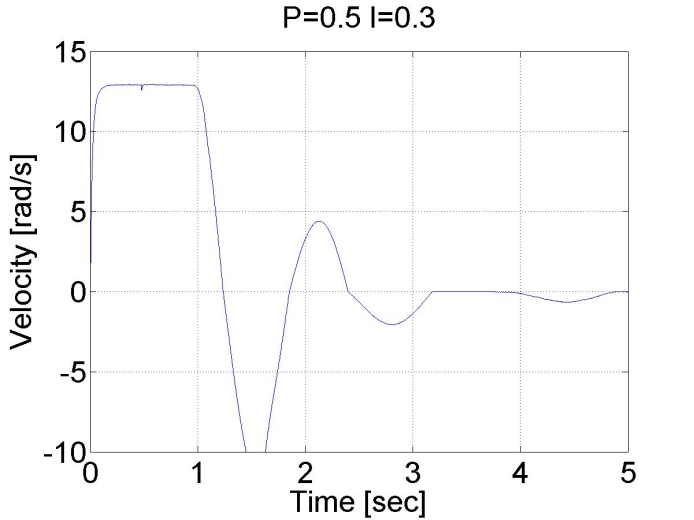

- 6.5.3. Response of the P controller to step changes in the reference speed signal -- Test 3.

- 6.5.4. Response of the P controller to step changes in the load -- Test 4.

- 6.5.5. Step signal response of the PI controller -- Test 2.

- 6.5.6. Response of the PI controller to step changes in the reference speed signal -- Test 3.

- 6.5.7. Response of the PI controller to step changes in the load -- Test 4.

- 6.5.8. Step signal response of the P and PI controller -- Test 1.

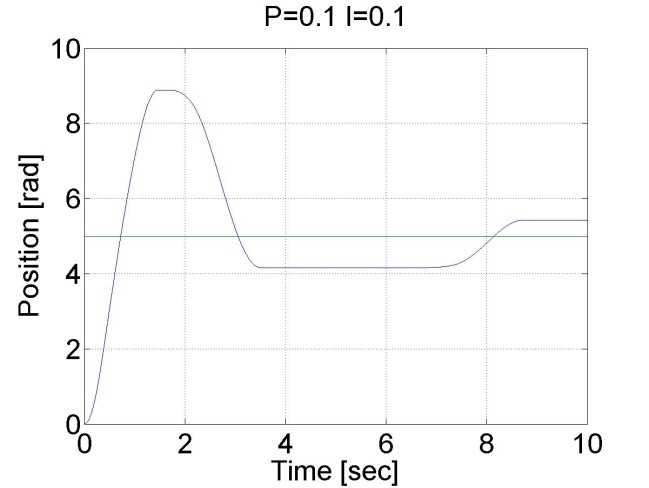

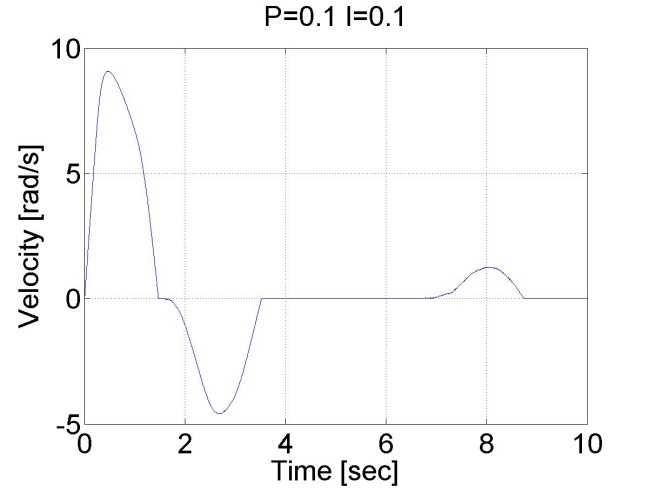

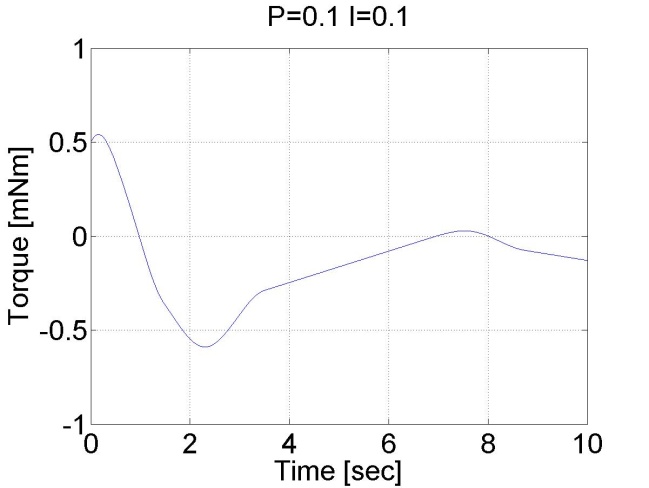

- 6.5.9. Stick-slip phenomenon

- 6.5.10. Step signal response of the position controller with inner shaft speed controller -- Test 1.

- 6.5.11. Fault tolerance measurements

- 6.5.12. Control of time-delay system

- 6.5.13. Sliding mode control results

- 6.6. Complex design and measurement

-

- 6.6.1. State feedback and its design

- 6.6.2. Application of reference signal correction

- 6.6.3. Design of the state observer

- 6.6.4. Integral control

- 6.6.5. Identification of the system

- 6.6.6. Design of the control

- 6.6.7. Identification of the motor

- 6.6.8. Design of the control

- 6.6.9. Integral control

- 6.6.10. Filter design for velocity measurement

- 6.6.11. Implementation

- 6.6.12. Control without integrator

- 6.6.13. Results of the measurement

- 6.6.14. Control with the integrator

- 6.6.15. Results of the measurement in the case of integrator

- 6.6.16. Appendix

6.1. Using the PCI-1720 D/A card -- Exercise 1

The code that is the solution and should be pasted into the code box is:

motorDA = 3;

new_voltage = 5.0;

//Step 1: Open device

dwErrCde = DRV_DeviceOpen(lDevNumDA, &lDriverHandleDA);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 2: Output value to the specified channel

tAOVoltageOut.chan = motorDA;

tAOVoltageOut.OutputValue = new_voltage;

dwErrCde = DRV_AOVoltageOut(lDriverHandleDA, &tAOVoltageOut);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleDA, dwErrCde);

return;

}

This code turns on the drive unit power. You should see the green LED on the drive unit lit.

To turn off the LED modify the following line: new_voltage = 0.0;

6.1.1. From the sample file (Dasoft.cpp) the following part should be copied to the text box:

//Step 3: Open device

dwErrCde = DRV_DeviceOpen(lDevNum, &lDriverHandle);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 4: Output value to the specified channel

tAOVoltageOut.chan = usChan;

tAOVoltageOut.OutputValue = fOutValue;

dwErrCde = DRV_AOVoltageOut(lDriverHandle, &tAOVoltageOut);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandle, dwErrCde);

printf("Press any key to exit....");

getch();

return;

}

6.1.2. Remove the code parts marked with red.

//Step 3: Open device

dwErrCde = DRV_DeviceOpen(lDevNum, &lDriverHandle);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 4: Output value to the specified channel

tAOVoltageOut.chan = usChan;

tAOVoltageOut.OutputValue = fOutValue;

dwErrCde = DRV_AOVoltageOut(lDriverHandle, &tAOVoltageOut);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandle, dwErrCde);

printf("Press any key to exit....");

getch();

return;

}

6.1.3. Change the code as it is highlighted with green.

motorDA = 3;

new_voltage = 5.0;

//Step 1: Open device

dwErrCde = DRV_DeviceOpen(lDevNumDA, &lDriverHandleDA);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 2: Output value to the specified channel

tAOVoltageOut.chan = motorDA;

tAOVoltageOut.OutputValue = new_voltage;

dwErrCde = DRV_AOVoltageOut(lDriverHandleDA, &tAOVoltageOut);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleDA, dwErrCde);

return;

}

Alternative solution can be achieved without using the predefined variables (motorDA and new_votlage). In this case the code is the following:

//Step 1: Open device

dwErrCde = DRV_DeviceOpen(lDevNumDA, &lDriverHandleDA);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 2: Output value to the specified channel

tAOVoltageOut.chan = 3;

tAOVoltageOut.OutputValue = 5.0f;

dwErrCde = DRV_AOVoltageOut(lDriverHandleDA, &tAOVoltageOut);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleDA, dwErrCde);

return;

}

6.2. Using the real-time clock with PCI 1720 D/A card – Exercise 2

The code, which the students should write into the variable box is:

float sin_amp = 3.0;

float sin_ang_freq = 0.25;

The code, which the students should write into the code box is:

new_voltage = sin_amp * sin(sin_ang_freq * (time_array[tickCount] / 10000000.0));

The division of 10000 is needed, to get the milliseconds and 1000 for the seconds.

The sin() function is a built in function of C++ and can be located in the Math.h header file. This function calculates the sinus of the given value.

If you use other variable than new_voltage the program will not work. The result is:

You can directly write in the values, without creating variables for it. In this case the text looks like the following:

new_voltage = 3.0 * sin(0.25 * (time_array[tickCount] / 10000000.0));

6.3. Using the PCI-1784 Counter card -- Exercise 3

The code that is the solution and should be pasted into the first text box (Initialization) is:

//Step 1: Open device

dwErrCde = DRV_DeviceOpen(lDevNumCounter, &lDriverHandleCounter);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 2: Reset counter by DRV_CounterReset

dwErrCde = DRV_CounterReset(lDriverHandleCounter, wChannelCounter);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 3: Start counter operation by DRV_CounterEventStart

tCounterEventStart.counter = wChannelCounter;

dwErrCde = DRV_CounterEventStart(lDriverHandleCounter, &tCounterEventStart);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 4: Read counter value by DRV_CounterEventRead

tCounterEventRead.counter = wChannelCounter;

tCounterEventRead.overflow = &wOverflow;

tCounterEventRead.count = &dwReading;

dwErrCde = DRV_CounterEventRead(lDriverHandleCounter, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleCounter, dwErrCde);

return;

}

The code that is the solution and should be pasted into the second text box (Inside loop) is:

dwErrCde = DRV_CounterEventRead(lDriverHandleCounter, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleCounter, dwErrCde);

return;

}

The results are the position and velocity graphs for a sinus torque.

6.3.1. From the sample file (Dasoft.cpp) the following part should be copied to the text box:

//Step 3: Open device

dwErrCde = DRV_DeviceOpen(lDevNum, &lDriverHandle);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 4: Reset counter by DRV_CounterReset

dwErrCde = DRV_CounterReset(lDriverHandle, wChannel);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 5: Start counter operation by DRV_CounterEventStart

tCounterEventStart.counter = wChannel;

dwErrCde = DRV_CounterEventStart(lDriverHandle, &tCounterEventStart);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 6: Read counter value by DRV_CounterEventRead in while loop

// and display counter value, exit when pressing any key

tCounterEventRead.counter = wChannel;

tCounterEventRead.overflow = &wOverflow;

tCounterEventRead.count = &dwReading;

while( !kbhit() )

{

dwErrCde = DRV_CounterEventRead(lDriverHandle, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandle, dwErrCde);

return;

}

printf("\nCounter value = %lu", dwReading);

Sleep(1000);

}

6.3.2. Remove the code parts marked with red.

//Step 3: Open device

dwErrCde = DRV_DeviceOpen(lDevNum, &lDriverHandle);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 4: Reset counter by DRV_CounterReset

dwErrCde = DRV_CounterReset(lDriverHandle, wChannel);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 5: Start counter operation by DRV_CounterEventStart

tCounterEventStart.counter = wChannel;

dwErrCde = DRV_CounterEventStart(lDriverHandle, &tCounterEventStart);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

printf("Program terminated!\n");

printf("Press any key to exit....");

getch();

exit(1);

}

// Step 6: Read counter value by DRV_CounterEventRead in while loop

// and display counter value, exit when pressing any key

tCounterEventRead.counter = wChannel;

tCounterEventRead.overflow = &wOverflow;

tCounterEventRead.count = &dwReading;

while( !kbhit() )

{

dwErrCde = DRV_CounterEventRead(lDriverHandle, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandle, dwErrCde);

return;

}

printf("\nCounter value = %lu", dwReading);

Sleep(1000);

}

6.3.3. Change the code as it is highlighted with green.

//Step 1: Open device

dwErrCde = DRV_DeviceOpen(lDevNumCounter, &lDriverHandleCounter);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 2: Reset counter by DRV_CounterReset

dwErrCde = DRV_CounterReset(lDriverHandleCounter, wChannelCounter);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 3: Start counter operation by DRV_CounterEventStart

tCounterEventStart.counter = wChannelCounter;

dwErrCde = DRV_CounterEventStart(lDriverHandleCounter, &tCounterEventStart);

if (dwErrCde != SUCCESS)

{

ErrorHandler(dwErrCde);

exit(1);

}

// Step 4: Read counter value by DRV_CounterEventRead

tCounterEventRead.counter = wChannelCounter;

tCounterEventRead.overflow = &wOverflow;

tCounterEventRead.count = &dwReading;

dwErrCde = DRV_CounterEventRead(lDriverHandleCounter, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleCounter, dwErrCde);

return;

}

Inside loop:

dwErrCde = DRV_CounterEventRead(lDriverHandleCounter, &tCounterEventRead);

if (dwErrCde != SUCCESS)

{

ErrorStop(&lDriverHandleCounter, dwErrCde);

return;

}

6.4. Open Loop Control measurement – Motion control/Exercise 4. Open-loop test

For the open loop test, we can do several tests. The output voltage can be calculated from the motor parameters. As there is no feedback in this control, we do not have knowledge about the actual shaft speed of the motor and the disturbance is fully present.

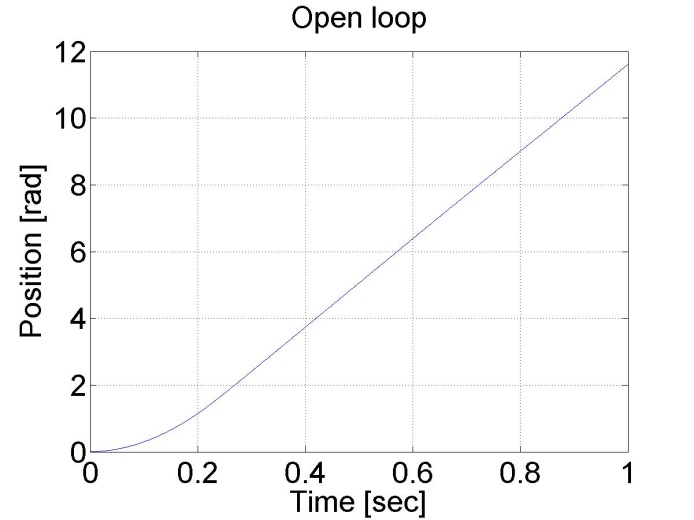

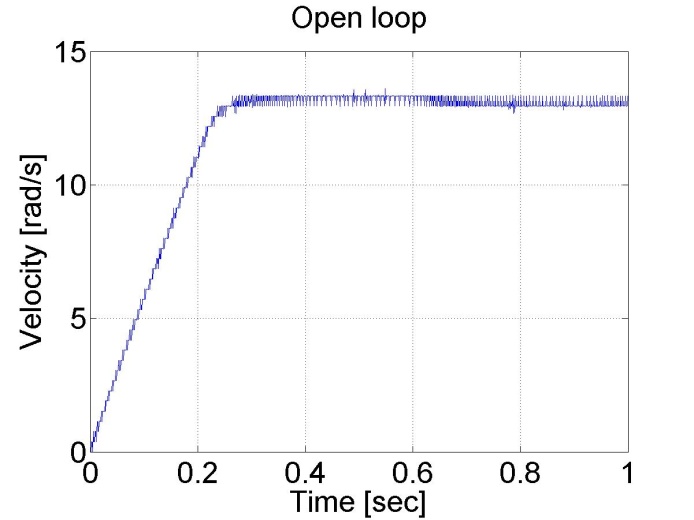

6.4.1. Task 1. Response of the motor to constant torque

The motor was tested with different output torque in this case. 0.1 was applied in the first case and 1 in the second case. The controller has the following form without any declarations:

Measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

Declaration:

Controller:

ResultData.Torque = 1;

or

ResultData.Torque = 0.1;

The results can be seen in the figure bellow. We can see that the position and the shaft speed diagram that the motor has a constant acceleration until it reaches its final shaft speed. The open loop control is very slow because of the constant voltage applied.

6.4.2. Task 2. Digital filter

The motor was tested with different output torque in this case. In the first case was applied 0.1 and 1 in the second case.

Measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

Declaration:

/* velocity filter variables */ static float z_1=0.0, z_2=0.0, z_3=0.0; static float ztmp_1=0.0, ztmp_2=0.0; /* velocity filter parameters */ /* TSAMPLE=1e-3 and Tc=0.007 */ float ad11= 0.9996, ad12= 9.9072e-004, ad13= 4.3344e-007; float ad21= -1.2637, ad22= 0.9730, ad23= 8.0496e-004; float ad31= -2.3468e+003, ad32= -50.5468, ad33= 0.6280; float bd1= 4.3671e-004, bd2= 1.2637, bd3= 2.3468e+003;

Controller:

/* Velocity filter */ ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity; ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity; z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity; z_1 = ztmp_1; z_2 = ztmp_2; ResultData.Velocity =z_1; ResultData.Torque = 1;

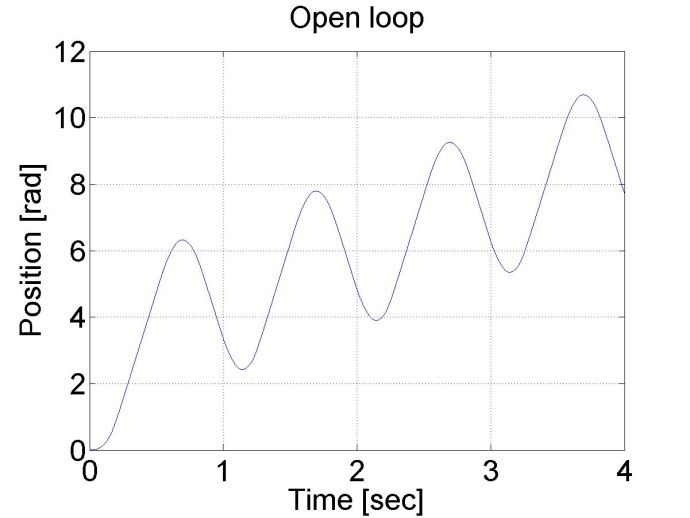

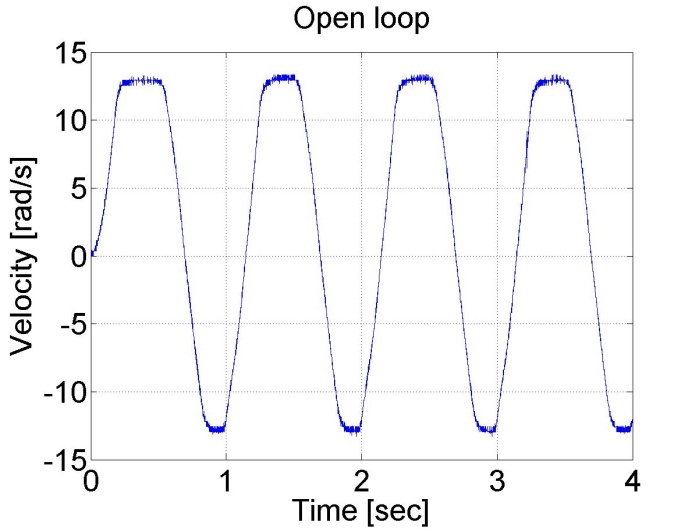

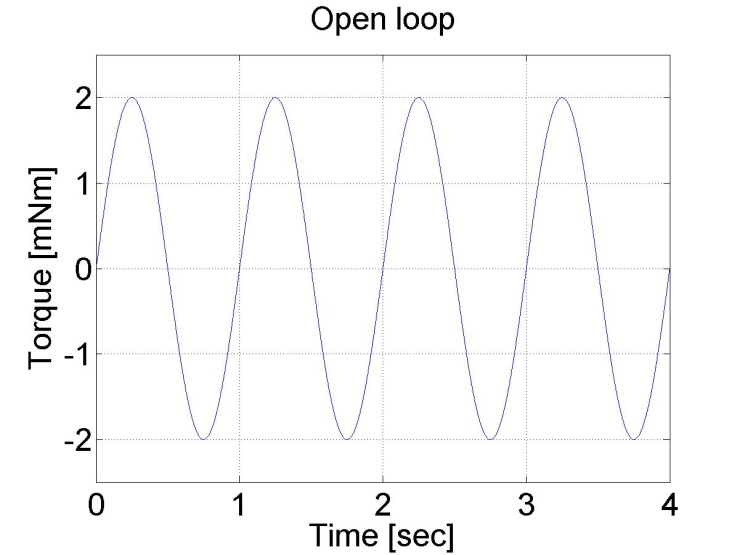

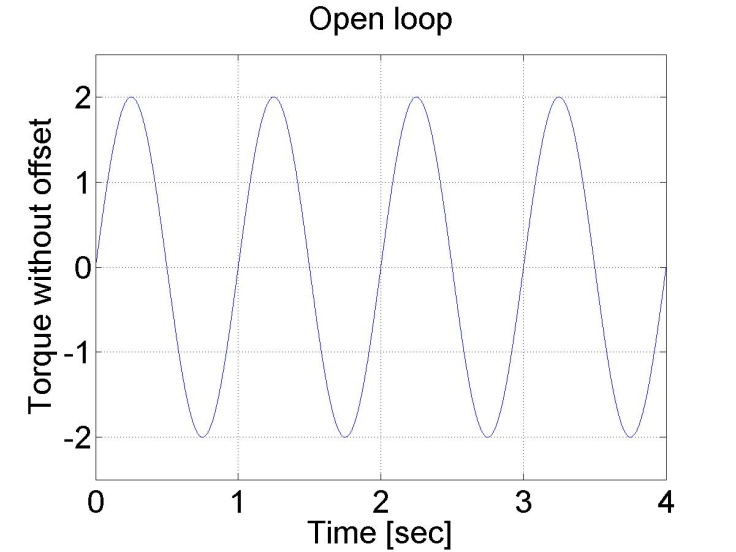

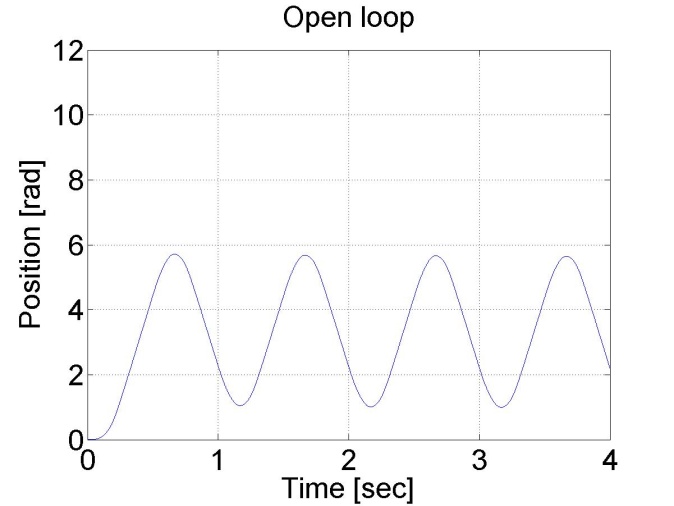

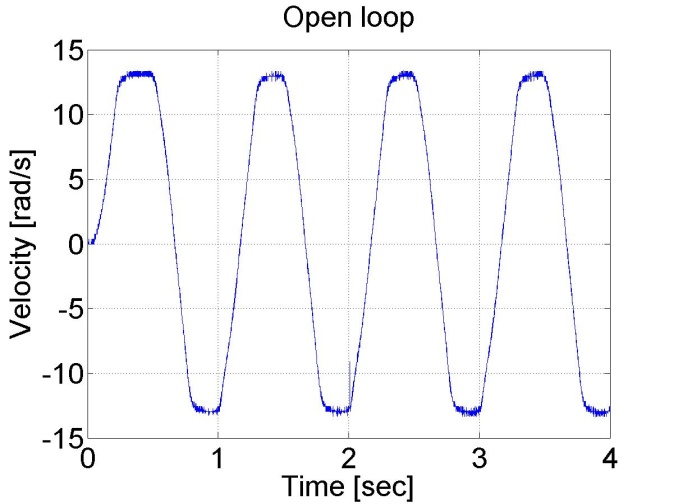

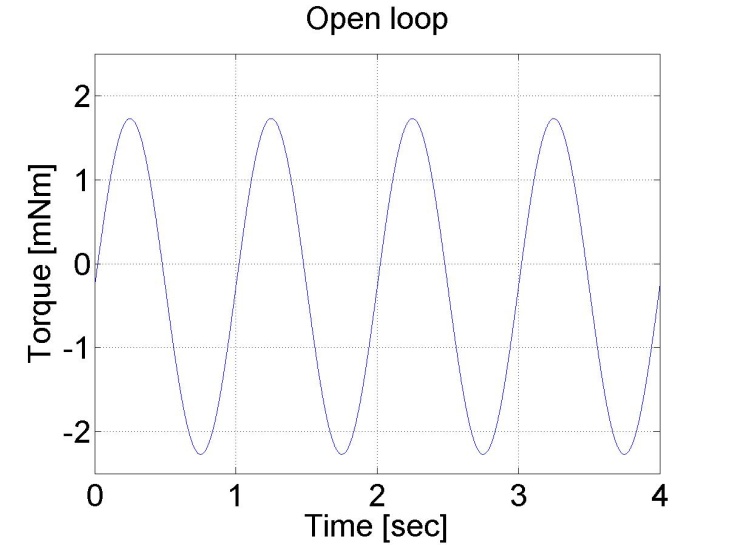

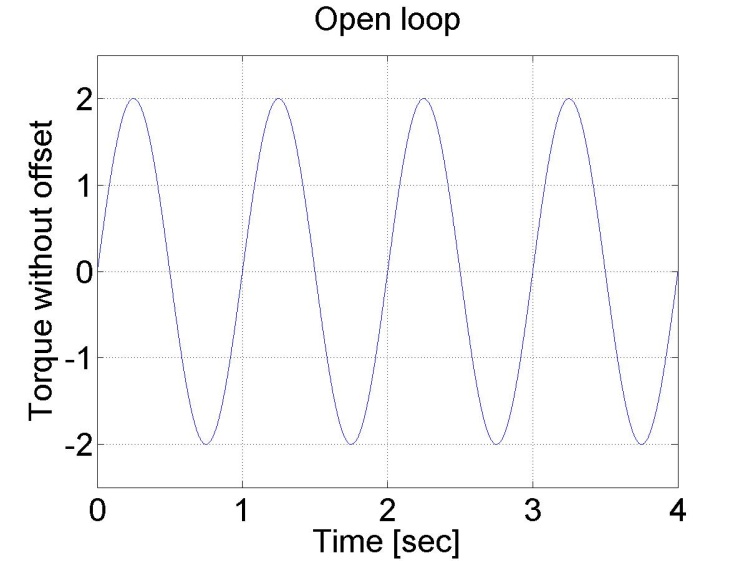

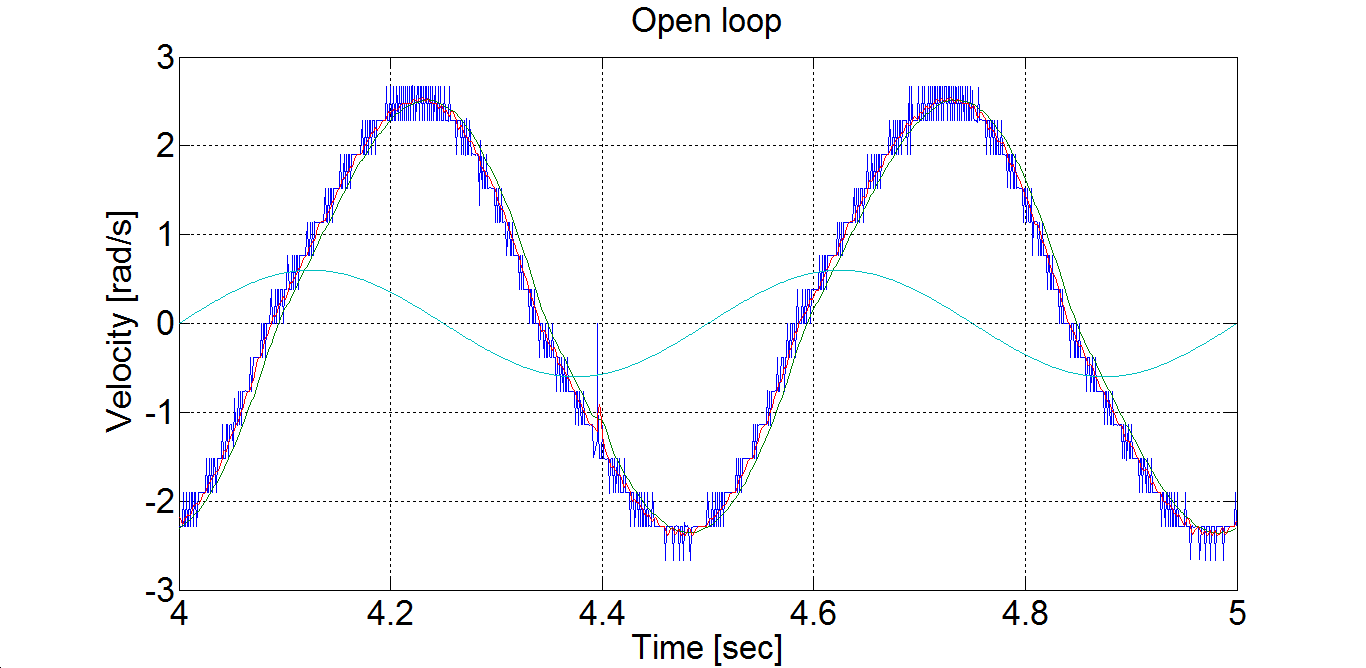

6.4.3. Task 3. Response of the motor to sinusoidal voltage and compensation of the servo amplifier offset

The servo amplifier of has an offset voltage. This is the most obvious if we apply a sinusoidal voltage. In this case we expect the motor to have sinusoidal shaft speed and sinusoidal position change coming from the shaft speed.

Measurement length in milliseconds : 4000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

sin_torque (selected)

Declaration:

doubleparam = 0; doublesinperiod = 1; doublesinamplitude = 2; doubleoffset = 0; // please, change the offset in the range of -0.3 and -0.2

Controller:

// Current time in miliseconds param = CurrentTime; // Current time in seconds param /= 1000; // Result param = param * 2 * PI / sinperiod; // // Controller part begin // // Sinusoidal voltage ResultData.Torque = sinamplitude * sin(param) + offset; ResultData.StateVariable_5 = sinamplitude * sin(param); // // Controller part end

The results can be seen in the figure bellow. The position diagram is not pure sinusoidal, but it has a linear component too. This linear component is the offset of the servo amplifier. This can be subtracted from the applied voltage and this way the linear component in the position diagram disappears. The only change in the controller is in the declaration:

doubleoffset = -0.27;

The MATLAB program to plot the results

% please, modify it according to you file names

sv_1_14axc255hnyzli55axowlm55

sv_2_14axc255hnyzli55axowlm55

sv_3_14axc255hnyzli55axowlm55

sv_4_14axc255hnyzli55axowlm55

sv_5_14axc255hnyzli55axowlm55

time=time/1000;

plot(time,position)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Position [rad]');

title('Open loop');

% you can adjust your axis

axis([0 4 0 12]);

grid

pause;

print -djpeg open_poz

plot(time,velocity)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Velocity [rad/s]');

title('Open loop');

% you can adjust your axis

axis([0 4 -15 15]);

grid

print -djpeg open_vel

pause;

plot(time,torque)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Torque [mNm]');

title('Open loop');

% you can adjust your axis

axis([0 4 -2.5 2.5]);

grid

print -djpeg open_torque

pause;

plot(time,sin_torque)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Torque without offset');

title('Open loop');

% you can adjust your axis

axis([0 4 -2.5 2.5]);

grid

print -djpeg open_sin

|

|

|

|

|

|

(a)

|

|

|

|

|

|

(b)

6.4.4. Comparison of digital filters

Measurement length in milliseconds : 4000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

sin_torque (selected)

-

ref (selected)

-

filt (selected)

-

filtb (selected)

Declaration:

doubleparam = 0; doublesinperiod = 0.1; doublesinamplitude = 0.6; doubleoffset = -0.217; /* variables for filter */ static float z_1=0.0, z_2=0.0, z_3=0.0; static float ztmp_1=0.0, ztmp_2=0.0; /* Tsample=1e-3 Tc=0.0032*/ float ad11 = 0.99591; float ad12 = 0.00095987; float ad13 = 3.652e-007; float ad21 = -11.3235; float ad22 = 0.88778; float ad23 = 0.00061567; float ad31 = -19089.6748; float ad32 = -193.6165; float ad33 = 0.30752; float bd1 = 0.0040906; float bd2 = 11.3235; float bd3 = 19089.6748; /* Variables for Bessel filter */ static float z_1b=0.0, z_2b=0.0, z_3b=0.0; static float ztmp_1b=0.0, ztmp_2b=0.0; /* Bessel Tsample=1e-3 Tc=0.0032*/ float ad11b = 0.95193; float ad12b = 0.00083371; float ad13b = 2.6009e-007; float ad21b = -120.9668; float ad22b = 0.56688; float ad23b = 0.00034345; float ad31b = -159737.83; float ad32b = -629.4281; float ad33b = -0.080513; float bd1b = 0.048071; float bd2b = 120.9668; float bd3b = 159737.83;

Controller:

// Current time param = CurrentTime; // Only milliseconds param /= 1000; // Result param = param * 2 * PI / sinperiod; // // Controller part begin // // Sinusoidal voltage ResultData.Torque = sinamplitude * sin(param) + offset; ResultData.StateVariable_5 = sinamplitude * sin(param); /* Velocity filter */ ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity; ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity; z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity; z_1 = ztmp_1; z_2 = ztmp_2; ResultData.StateVariable_6=z_1; /* Bessel velocity filter */ ztmp_1b=ad11b* z_1b+ad12b* z_2b+ad13b* z_3b + bd1b* ResultData.Velocity; ztmp_2b=ad21b* z_1b+ad22b* z_2b+ad23b* z_3b + bd2b* ResultData.Velocity; z_3b=ad31b* z_1b+ad32b* z_2b+ad33b* z_3b + bd3b* ResultData.Velocity; z_1b = ztmp_1b; z_2b = ztmp_2b; ResultData.StateVariable_7=z_1b;

Measurement with two different frequency

doublesinperiod = 0.1;

and

doublesinperiod = 0.5;

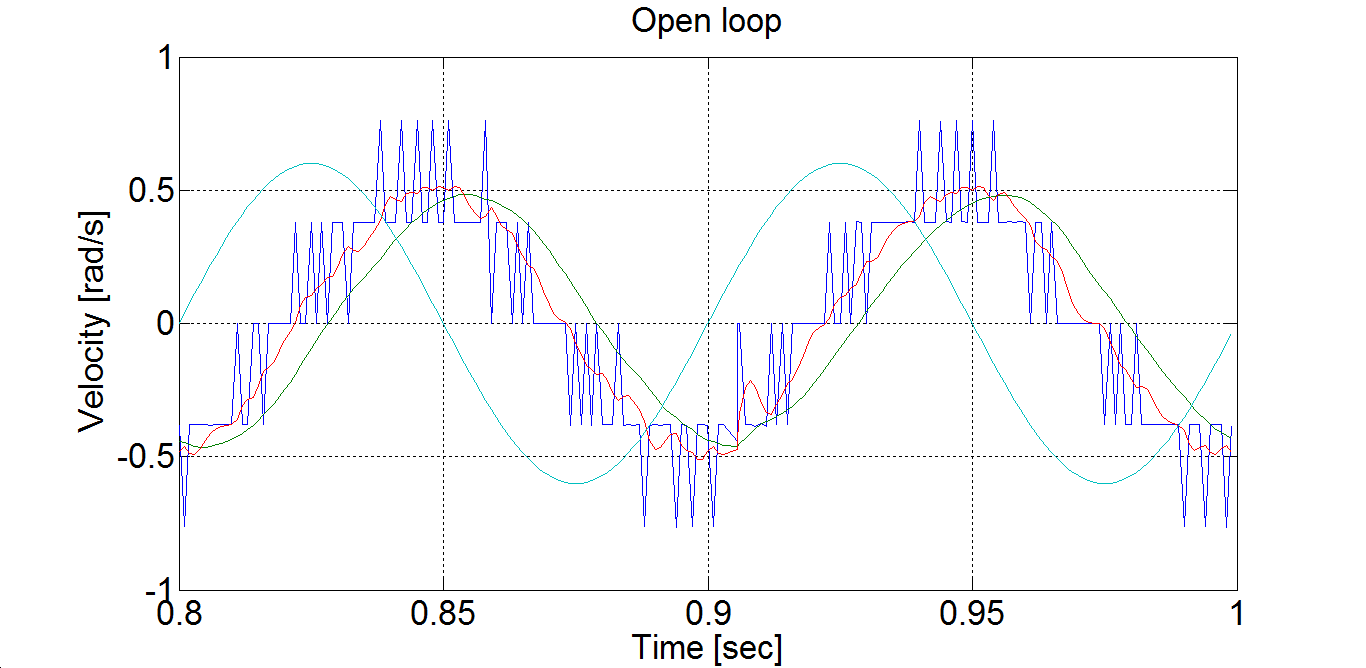

The steady state are plotted in Figure 6-1 and Figure 6-2

The MATLAB program for generating Figure 6-1 and Figure 6-2

sv_1_zlwzmf45pqyn1c45p31cvve4

sv_2_zlwzmf45pqyn1c45p31cvve4

sv_3_zlwzmf45pqyn1c45p31cvve4

sv_4_zlwzmf45pqyn1c45p31cvve4

sv_5_zlwzmf45pqyn1c45p31cvve4

sv_6_zlwzmf45pqyn1c45p31cvve4

sv_7_zlwzmf45pqyn1c45p31cvve4

plot(time,velocity,time,filt,time,filtb,time,ref)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Velocity [rad/s]');

title('Open loop');

% you can adjust your axis

% axis([0.8 1 -1 1]);

axis([4 5 -3 3]);

grid

print -djpeg open_vel

6.5. Closed Loop Control Measurements -- Exercise 5

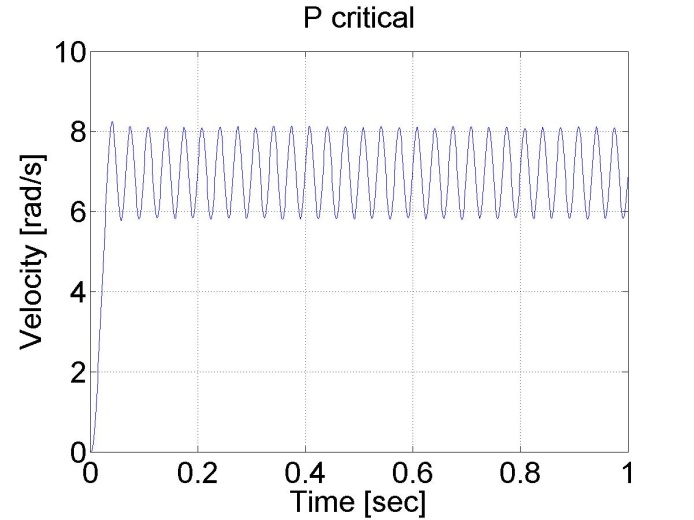

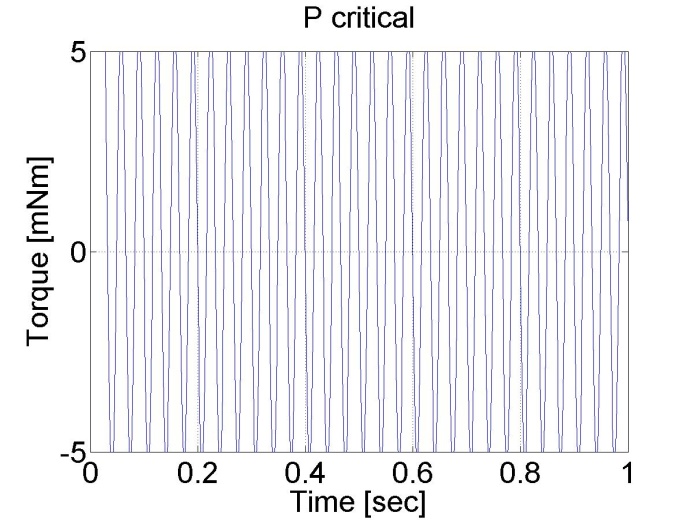

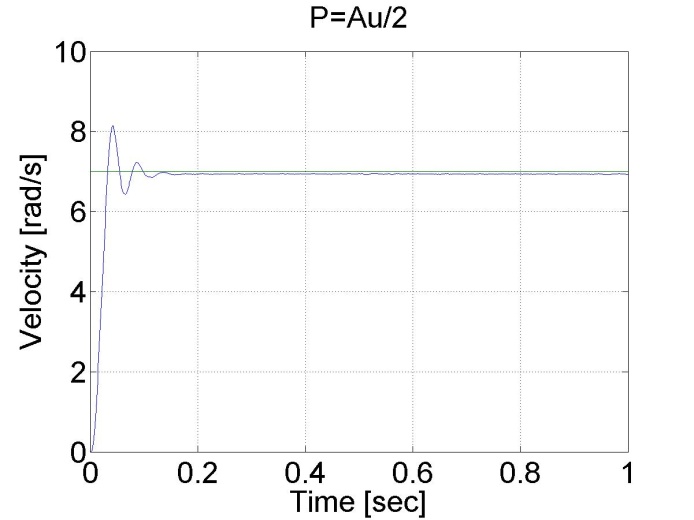

6.5.1. Parameter tuning of the P controller -- Test 1.

The first task in PID control is to tune the parameters of the controller. For this we used the Ziegler-Nichols method which is easy to implement empirically for the system even for a beginner in control theory. In the figure bellow the Ziegler-Nichols tuning chart can be seen.

|

AP |

I |

TD |

|

|

P control |

AU/2 |

||

|

PI control |

AU/2.2 |

1.2AP/Tu |

|

|

PID control zó |

AU/1.7 |

2AP/Tu |

AP Tu/8 |

The first step in the tuning is to create a P controller with arbitrary AU value. The controller has the following form:

Measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

Declaration:

doubleP = 4.75; doubleref_vel = 7; doubleerror_vel= 0; /* velocity filter variables */ static float z_1=0.0, z_2=0.0, z_3=0.0; static float ztmp_1=0.0, ztmp_2=0.0; /* velocity filter parameters */ /* TSAMPLE=1e-3 and Tc=0.005 */ float ad11= 0.9989, ad12= 9.8248e-004, ad13= 4.0937e-007; float ad21= -3.2749, ad22= 0.9497, ad23= 7.3686e-004; float ad31= -5.8949e+003, ad32= -91.6978, ad33= 0.5076; float bd1= 0.0011, bd2= 3.2749, bd3= 5.8949e+003;

Controller:

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.Torque = P*error_vel;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

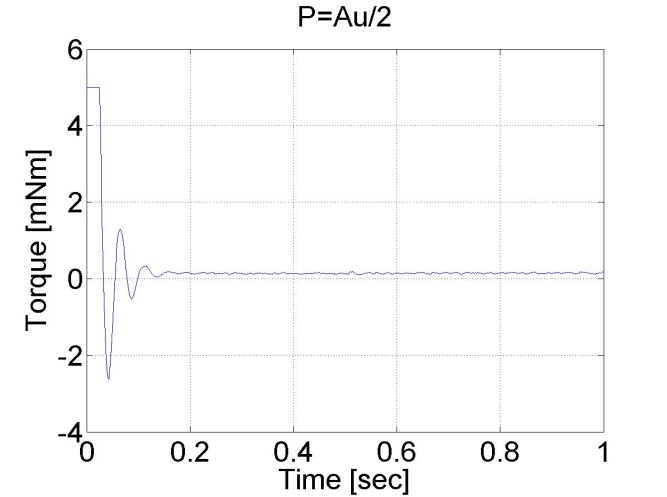

The controller also sets the minimal and maximal values of the output voltage to 5 and -5 V. The results can be seen in the figure bellow.

We can conclude that AU = 4.75 and TU≈0.2/6. According to the table PPI=2.1 and IPI=75.

Remark!!! the values of AU and TU depend on the filter parameter.

6.5.2. Step signal response of the P controller -- Test 2.

For this test we set the reference shaft speed to 1 rad/s. The controller has the following form:

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2.3;

doubleI_par = 0.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5) { ResultData.Torque = 5; }

if (ResultData.Torque < -5) { ResultData.Torque = -5; }

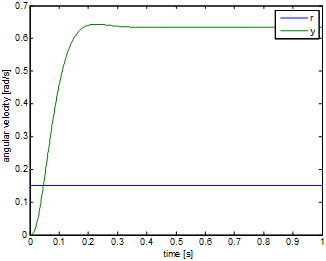

The results can be seen in the figure bellow. We can see that the P controller has a constant error in steady state.

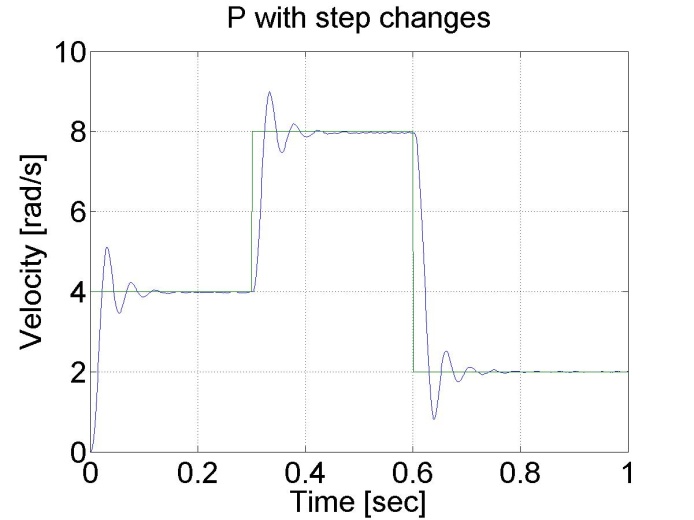

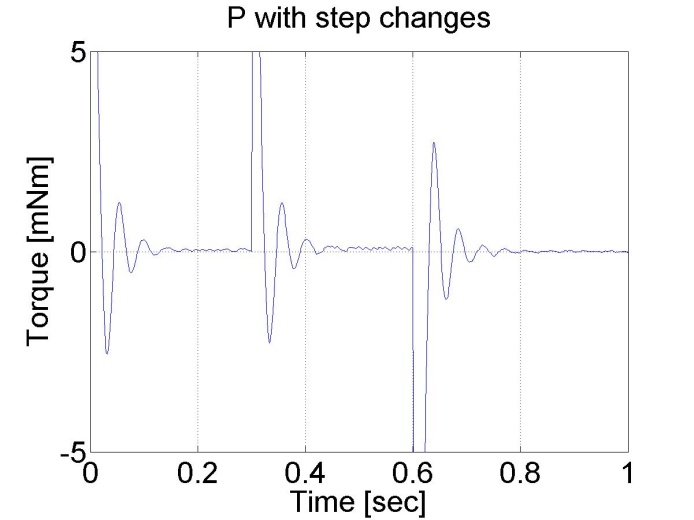

6.5.3. Response of the P controller to step changes in the reference speed signal -- Test 3.

In this test the reference shaft speed changed in two time instances, at t = 0.2 s and at t = 0.4 s. The constant error of the P controller is noticeable in this case too. The controller has the following form:

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2.3;

doubleI_par = 0.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

//Step changes in reference speed

if (CurrentTime > 0*1e3 && CurrentTime < 0.2*1e3)

{

ref_vel = 4;

}

if (CurrentTime >= 0.2*1e3 && CurrentTime < 0.4*1e3)

{

ref_vel = 8;

}

if (CurrentTime >= 0.4*1e3 && CurrentTime < 0.6*1e3)

{

ref_vel = 2;

}

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5) { ResultData.Torque = 5; }

if (ResultData.Torque < -5) { ResultData.Torque = -5; }

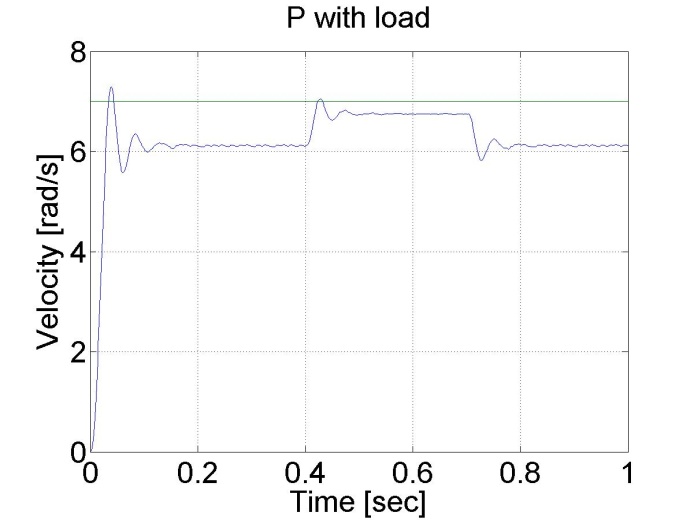

6.5.4. Response of the P controller to step changes in the load -- Test 4.

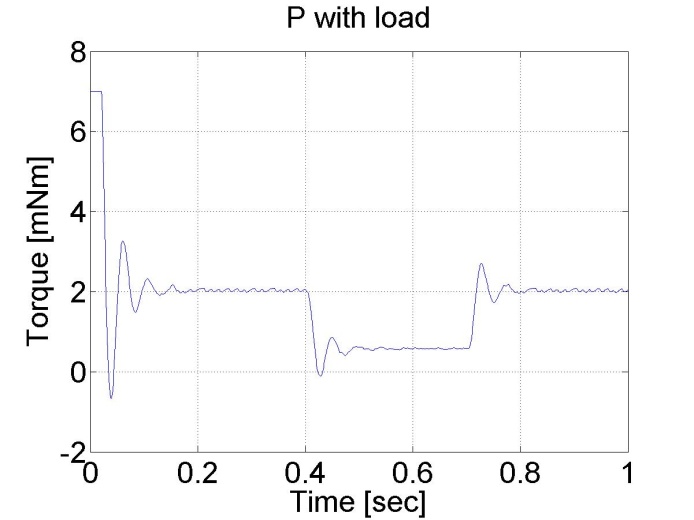

We can see the largest drawback of the P controller that it has a constant error and it is not able to reject disturbances.

Enter measurement length in milliseconds: 1000

The state variable names :

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2.3;

doubleI_par = 0.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 2;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

if (CurrentTime >= 0.4*1e3 && CurrentTime < 0.7*1e3)

{

load = 0.5;

}

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5) { ResultData.Torque = 5; }

if (ResultData.Torque < -5) { ResultData.Torque = -5; }

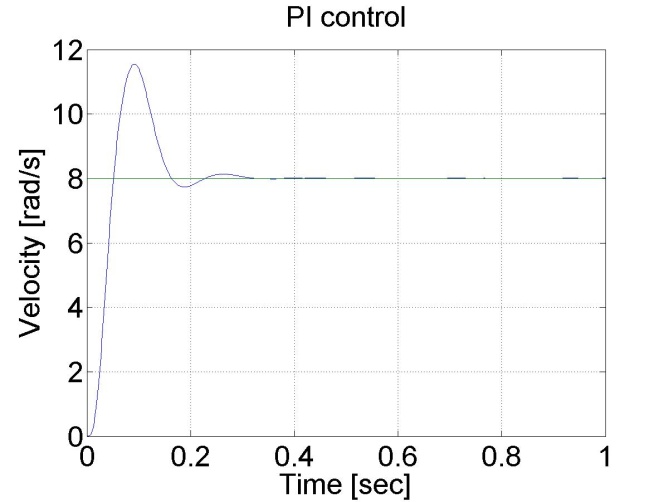

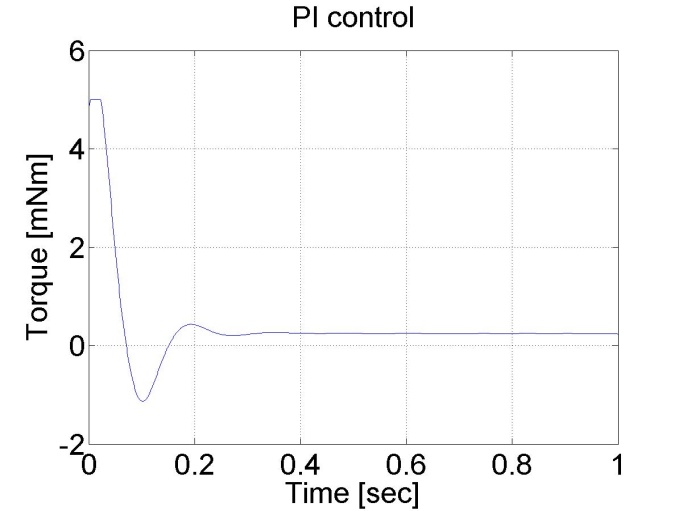

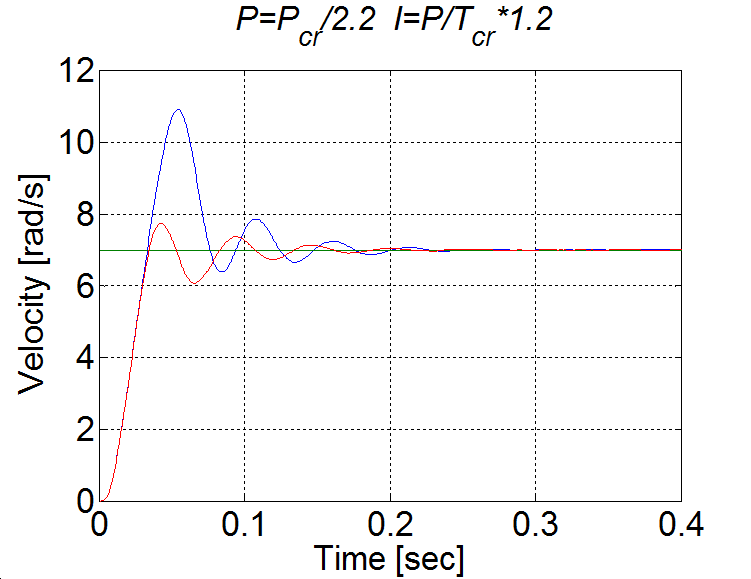

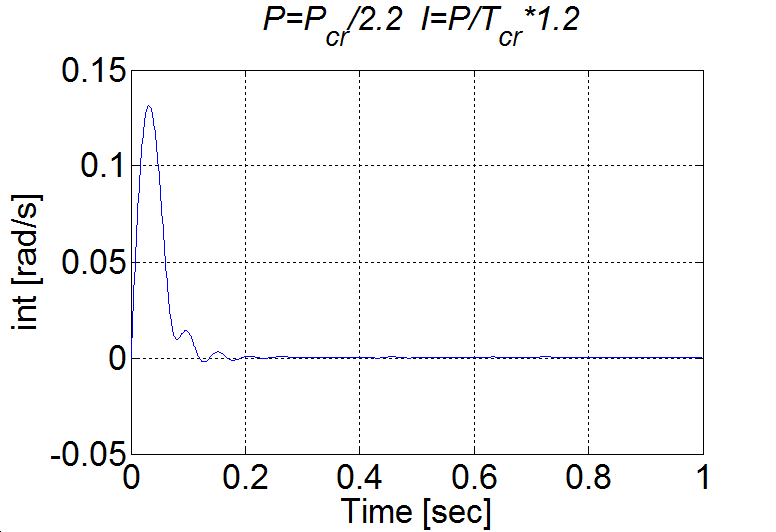

6.5.5. Step signal response of the PI controller -- Test 2.

For this test we set the reference shaft speed to 1 rad/s. The controller has the following form:

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP = 0.6;

doubleI = 7;

doubleref_vel = 8;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* velocity filter parameters */

/* TSAMPLE=1e-3 and Tc=0.007 */

float ad11= 0.9996, ad12= 9.9072e-004, ad13= 4.3344e-007;

float ad21= -1.2637, ad22= 0.9730, ad23= 8.0496e-004;

float ad31= -2.3468e+003, ad32= -50.5468, ad33= 0.6280;

float bd1= 4.3671e-004, bd2= 1.2637, bd3= 2.3468e+003;

Controller:

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000.0;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.StateVariable_8 = CurrentTime;

ResultData.Torque = P*error_vel + I*error_vel_int - load;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

The noticeable difference from the P controller is the lack of steady state error. This is the effect of the integral part of the controller, which summarizes the error. The integral error is also presented, which has a large value at the beginning and decreases afterwards. The PI controller is also faster form the P controller. Its drawback is, that is can lead to large overshot or even to instability. This can be eliminated by adding a D element to the controller.

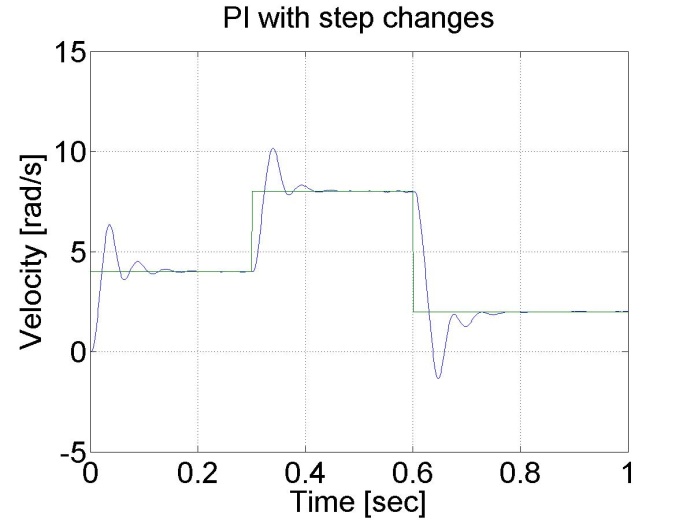

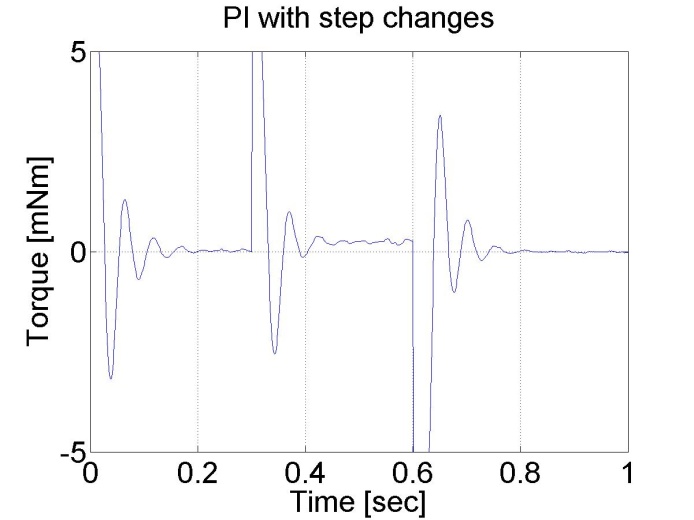

6.5.6. Response of the PI controller to step changes in the reference speed signal -- Test 3.

In this test the reference shaft speed changed in two time instances, at t = 0.3 s and at t = 0.6 s. The PI controller is faster compared to the P controller and the motor operates without steady state error. The controller has the following form:

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2;

doubleI_par = 50.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

//Step changes in reference speed

if (CurrentTime > 0*1e3 && CurrentTime < 0.3*1e3)

{

ref_vel = 4;

}

if (CurrentTime >= 0.3*1e3 && CurrentTime < 0.6*1e3)

{

ref_vel = 8;

}

if (CurrentTime >= 0.6*1e3 && CurrentTime < 1.6*1e3)

{

ref_vel = 2;

}

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5) { ResultData.Torque = 5; }

if (ResultData.Torque < -5) { ResultData.Torque = -5; }

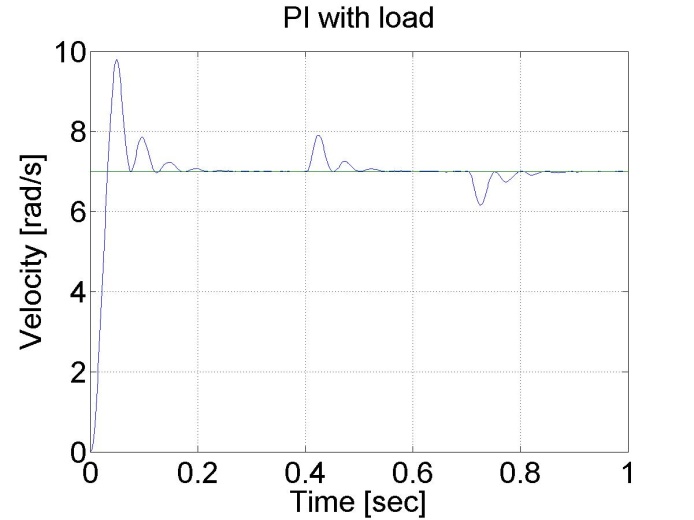

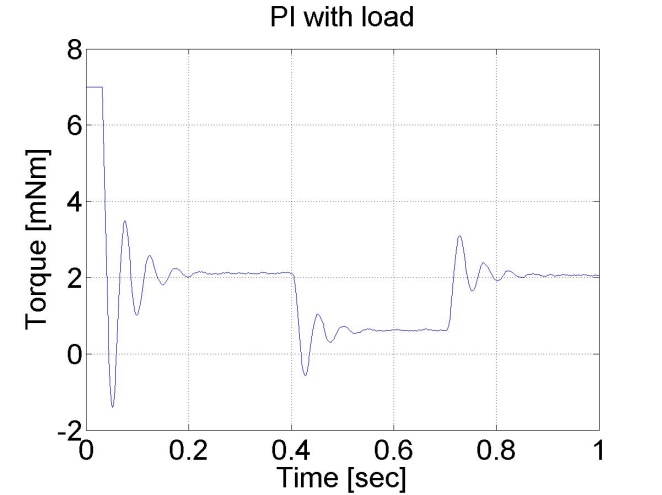

6.5.7. Response of the PI controller to step changes in the load -- Test 4.

In this test, a constant virtual load is added if t < 0.3 s than load=2.0 load, if 0.3 s<t < 0.7 s than load=0.5 finally if t >0.7 s than load=2.0 again.

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2.3;

doubleI_par = 50;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 2;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

if (CurrentTime >= 0.4*1e3 && CurrentTime < 0.7*1e3)

{

load = 0.5;

}

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000.0;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

We can notice that the PI controller is good at disturbance rejection on the contrary to the P controller.

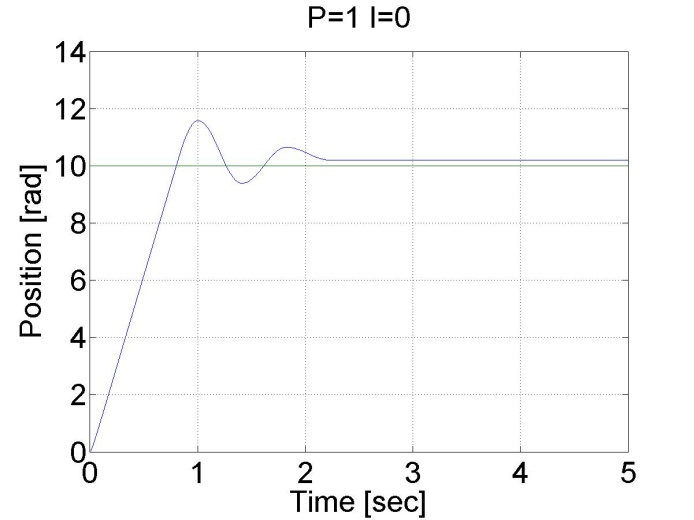

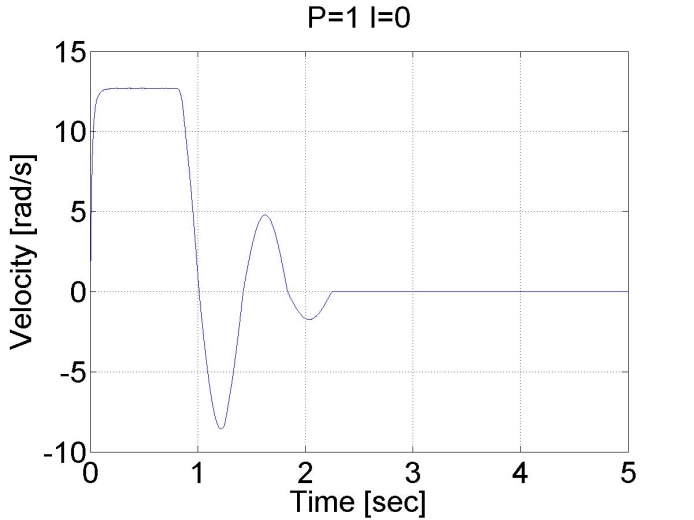

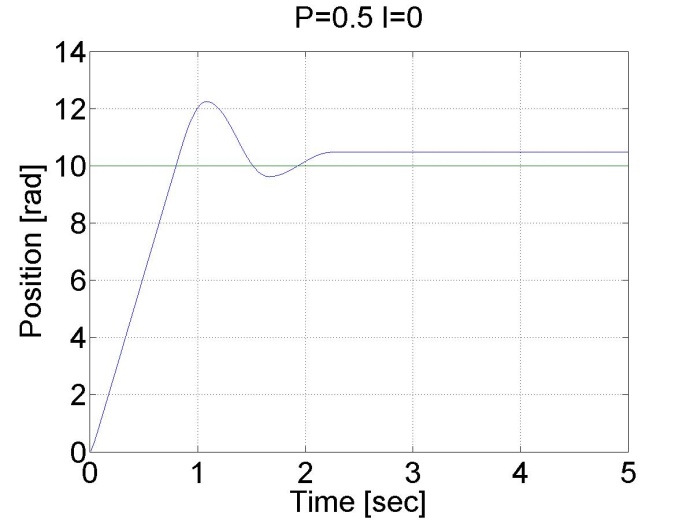

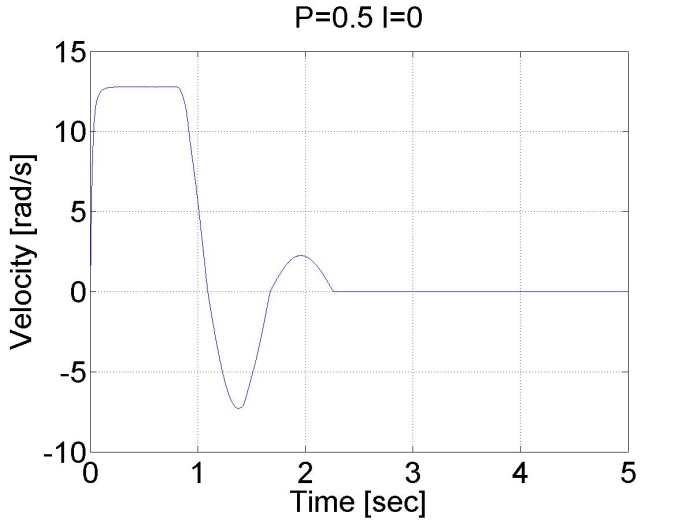

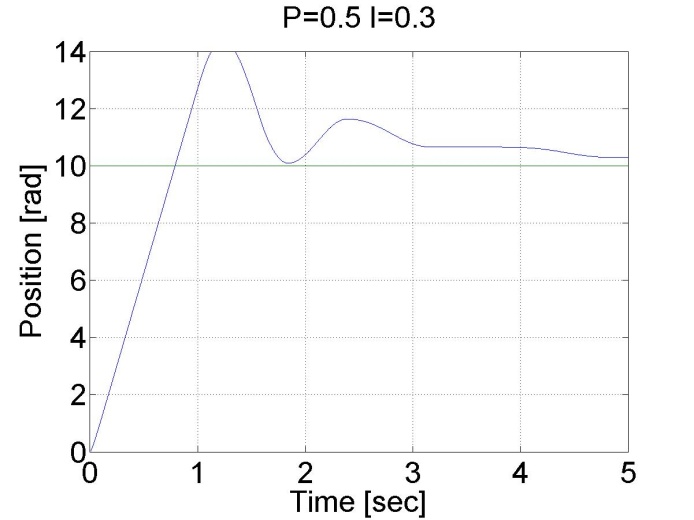

6.5.8. Step signal response of the P and PI controller -- Test 1.

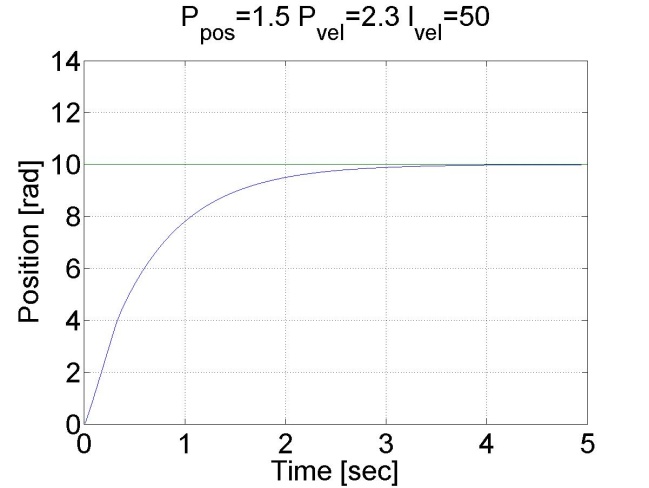

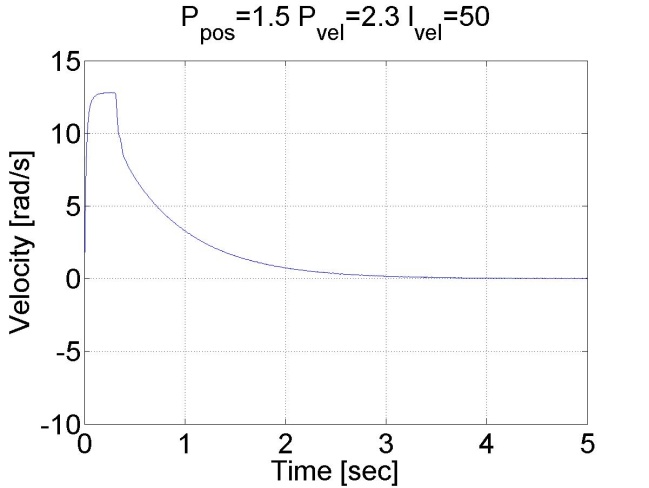

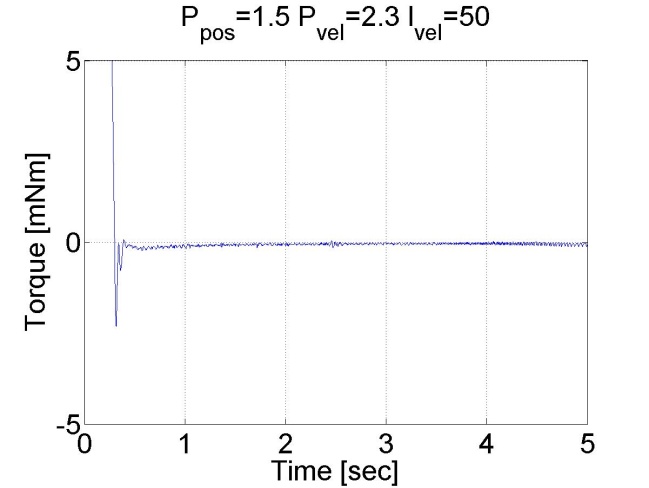

For this test we set the reference shaft position to 10 rad. The controller has the following form:

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 1;

doubleI_par = 0;

doubleref_pos = 10;

doubleerror_pos;

static doubleerror_pos_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

static double ini_0 = 0;

static double ini_1 = -10;

Controller:

if (ini_1 < 0)

{

ini_0 = ResultData.Position;

}

ini_1 = 5;

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_pos=ref_pos- ResultData.Position + ini_0;

error_pos_int = error_pos_int + error_pos*(CurrentTime - OldTime)/1000.0;

ResultData.StateVariable_5 = ref_pos;

ResultData.StateVariable_6 = error_pos;

ResultData.StateVariable_7 = error_pos_int;

ResultData.StateVariable_8 = ResultData.Position - ini_0;

ResultData.Torque = P_par*error_pos + I_par*error_pos_int - load;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

We can see that there is a large overshot in this controller, and the steady state error is also present. On the other hand, the position is measured and not calculated by derivation, the position curve is smooth compared to the shaft speed curves in the previous cases.

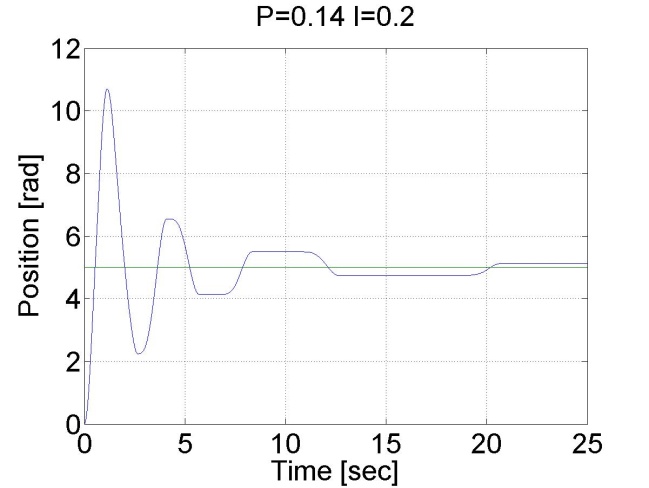

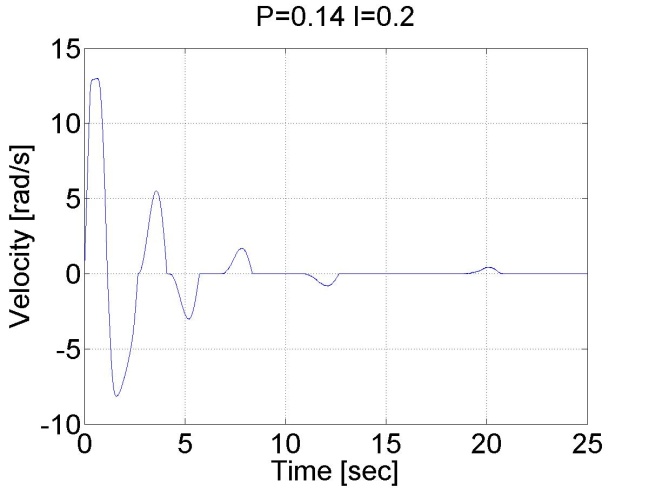

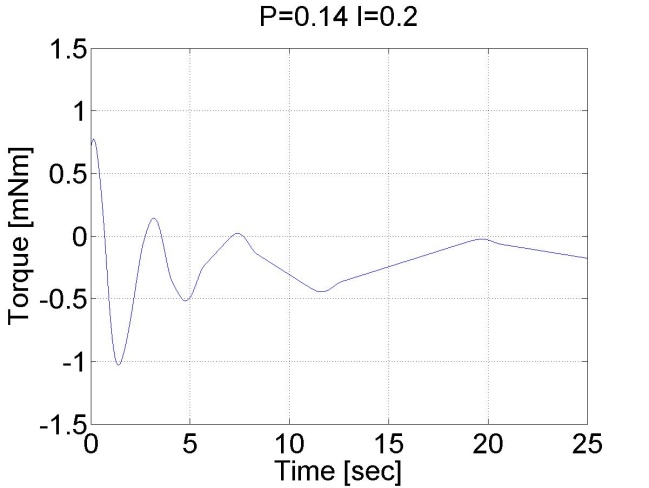

6.5.9. Stick-slip phenomenon

Enter measurement length in milliseconds: 10000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 0.1;

doubleI_par = 0.1;

doubleref_pos = 5;

doubleerror_pos;

static doubleerror_pos_int=0.0;

double load = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

static double ini_0 = 0;

static double ini_1 = -10;

Controller:

if (ini_1 < 0)

{

ini_0 = ResultData.Position;

}

ini_1 = 5;

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_pos=ref_pos- CurrentPosition;

error_pos_int = error_pos_int + error_pos*(CurrentTime - OldTime)/1000.0;

ResultData.StateVariable_5 = ref_pos;

ResultData.StateVariable_6 = error_pos;

ResultData.StateVariable_7 = error_pos_int;

ResultData.Torque = P_par*error_pos + I_par*error_pos_int - load;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

6.5.10. Step signal response of the position controller with inner shaft speed controller -- Test 1.

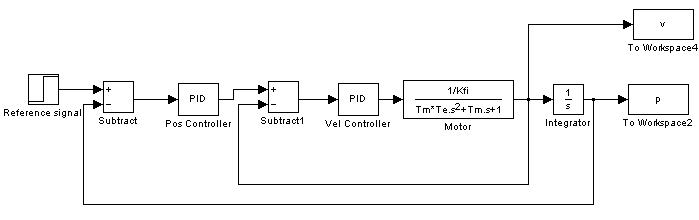

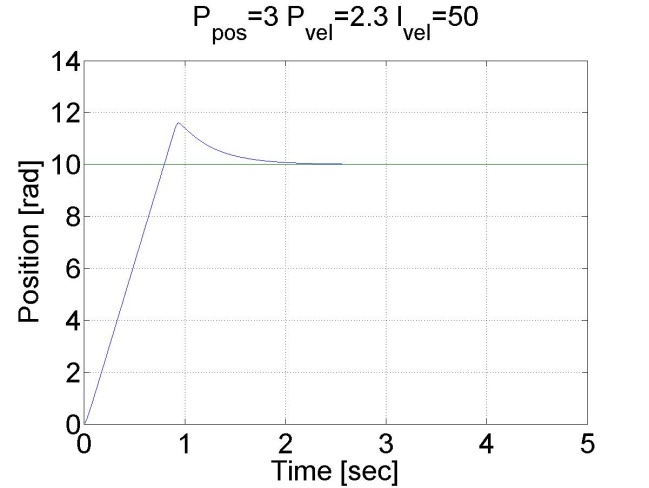

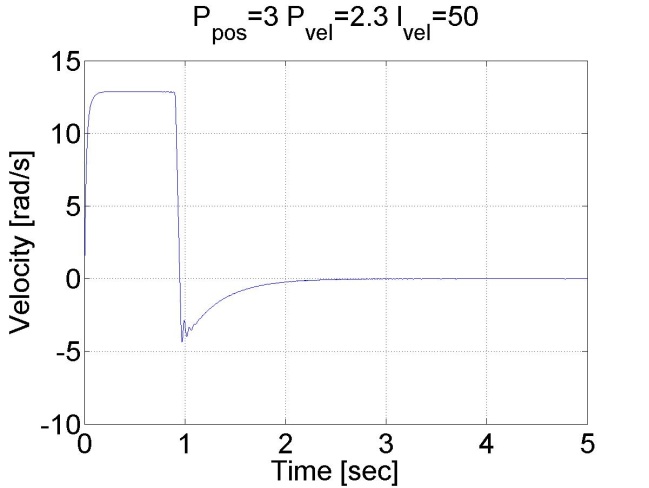

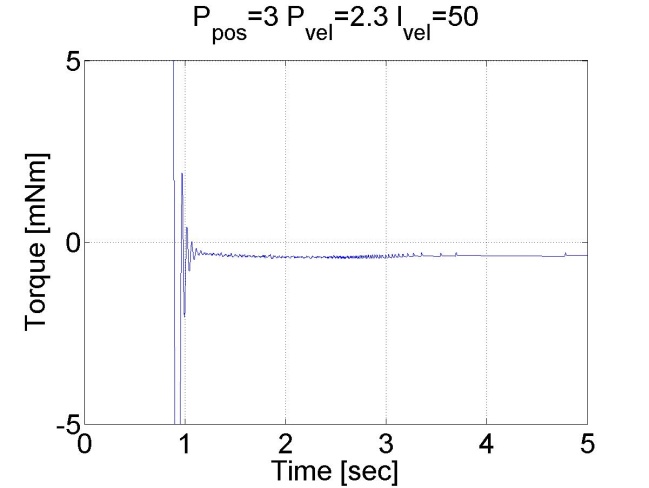

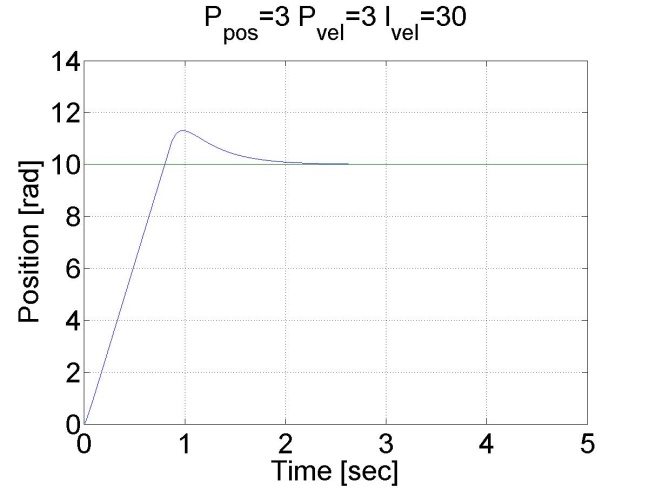

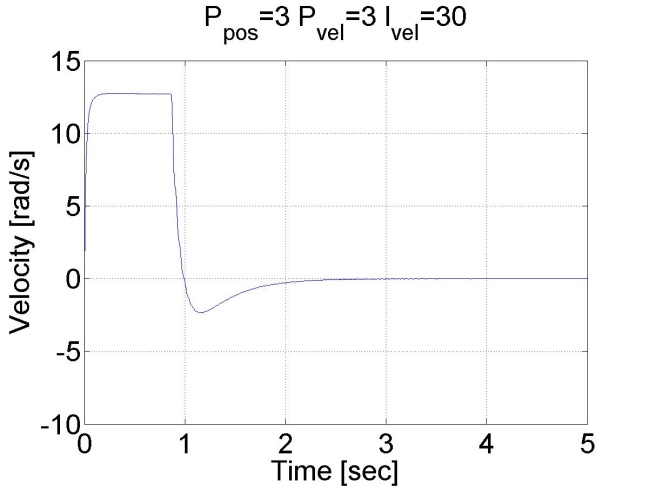

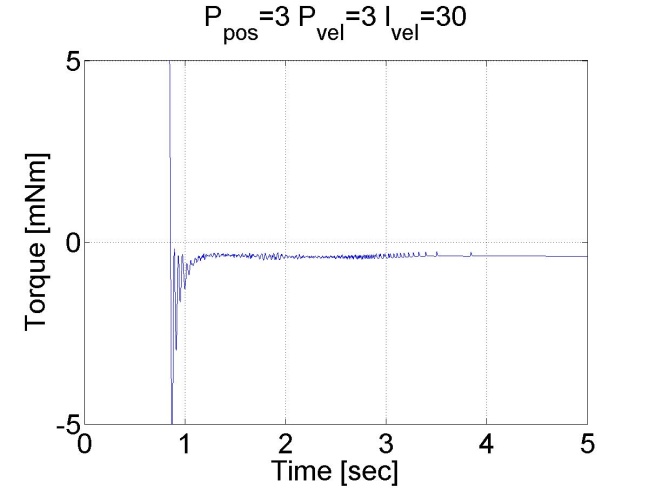

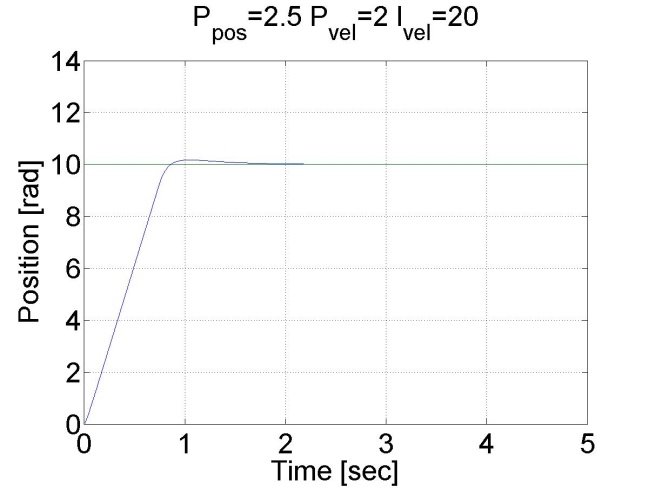

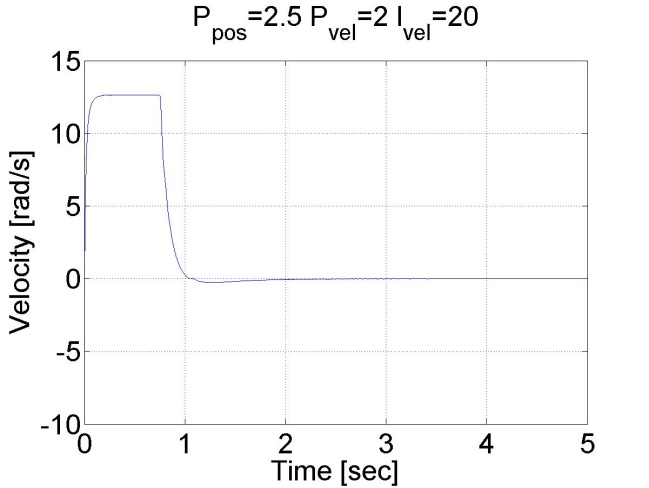

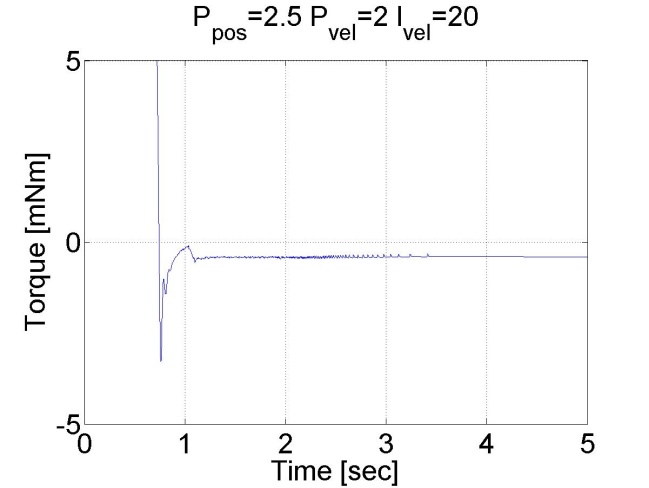

The motor reached the reference position. The reason for the overshot is that it takes time to decelerate the motor. This effect can be eliminated if we introduce an inner control loop for the shaft speed of the motor. The reference value for the shaft speed is coming from the position error of the motor, this means that as the motor reaches its reference position the reference shaft speed starts do decrease. The reference shaft speed is almost zero if the motor is close to the reference position. The structure of this controller can be seen in the figure bellow. The position controller is P type and the shaft speed controller is PI type.

The controller code is the following:

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref_poz (selected)

-

ref_vel (selected)

-

err_pos (selected)

-

err_vel (selected)

-

int_vel (selected)

-

poz (selected)

Declaration:

doubleP_pos = 3;

doubleP_vel = 3;

doubleI_vel = 30;

doubleref_pos = 10;

doubleref_vel = 0;

doubleerror_pos = 0;

doubleerror_vel = 0;

static doubleerror_vel_int = 0;

static doubleini_0 = 0;

static doubleini_1 = -10;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

if (ini_1 < 0)

{

ini_0 = ResultData.Position;

}

ini_1 = 5;

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for position control

error_pos = ref_pos- ResultData.Position + ini_0;

// Error calculation for velocity control

ref_vel = error_pos*P_pos;

error_vel = ref_vel - ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_pos;

ResultData.StateVariable_6 = ref_vel;

ResultData.StateVariable_7 = error_pos;

ResultData.StateVariable_8 = error_vel;

ResultData.StateVariable_9 = error_vel_int;

ResultData.StateVariable_10 = ResultData.Position - ini_0;

//Controller

ResultData.Torque = P_vel*error_vel + I_vel*error_vel_int;

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

We can see that there is no overshot in this case, because the shaft speed starts decreasing in time. We can conclude that position control with inner shaft speed control loop gives much better results than the simple P position controller.

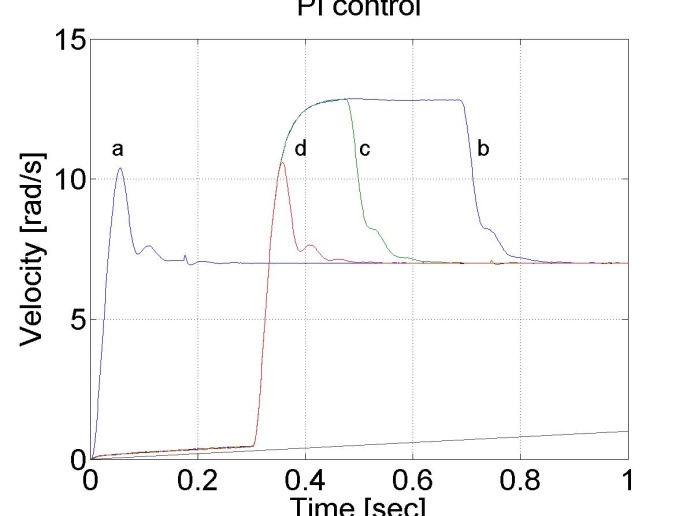

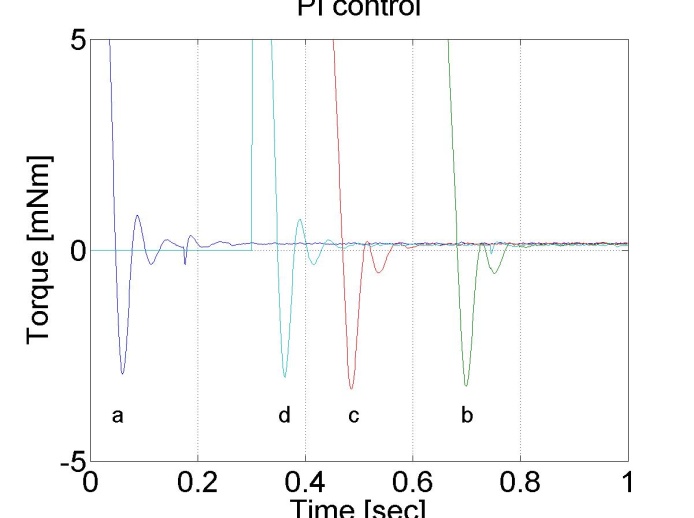

6.5.11. Fault tolerance measurements

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2;

doubleI_par = 50;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/*

// in case of a

doubleint_lim = 100;

doubleTf = -0.3*1e3;

// in case of b

doubleint_lim = 100;

doubleTf = 0.3*1e3;

// in case of c

doubleint_lim = 0.9;

doubleTf = 0.3*1e3;

// in case of d

doubleint_lim = 0.15;

doubleTf = 0.3*1e3;

*/

// Please, copy one of the above pair of parameters

doubleint_lim = 0.15;

doubleTf = 0.3*1e3;

Controller:

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* TSAMPLE=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000.0;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

if (error_vel_int > int_lim)

{

error_vel_int = int_lim;

}

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if ( CurrentTime < Tf)

{

ResultData.Torque = 0.0;

}

if (ResultData.Torque > 5)

{

ResultData.Torque = 5;

}

if (ResultData.Torque < -5)

{

ResultData.Torque = -5;

}

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 2.1;

doubleI_par = 75.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 2;

double delta = 0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* Tsample=1e-3 and Tc=0.0027 */

float ad11= 0.9936, ad12= 9.4621e-004, ad13= 3.4524e-007;

float ad21= - 17.5400, ad22= 0.8515, ad23= 5.6261e-004;

float ad31= -2.8584e+004, ad32= -249.0676, ad33= 0.2264;

float bd1= 0.0064, bd2= 17.5400, bd3= 2.8584e+004;

Controller:

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

delta=error_vel*(CurrentTime - OldTime)/1000;

error_vel_int = error_vel_int + delta;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.Torque = P_par*error_vel + I_par*error_vel_int - load;

if (ResultData.Torque > 5) { ResultData.Torque = 5; error_vel_int = error_vel_int - delta*0; }

if (ResultData.Torque < -5) { ResultData.Torque = -5; error_vel_int = error_vel_int - delta*0;}

ResultData.StateVariable_7 = error_vel_int;

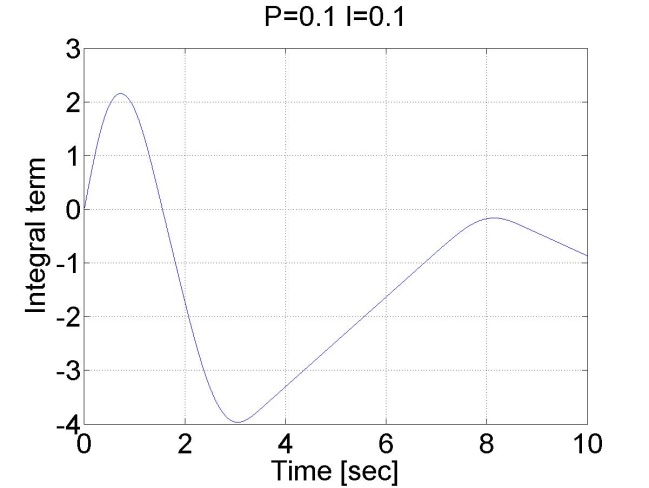

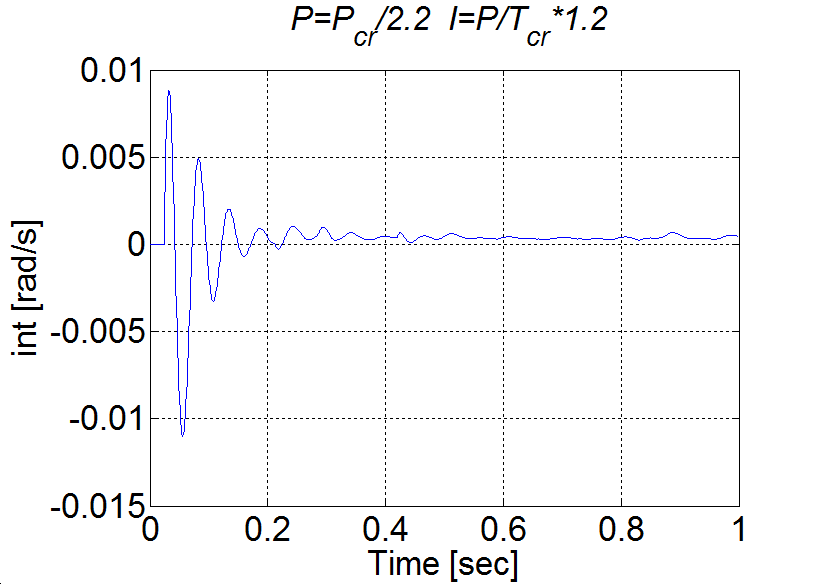

The oveshoot can be reduced by switching off the integrator term during controller saturation

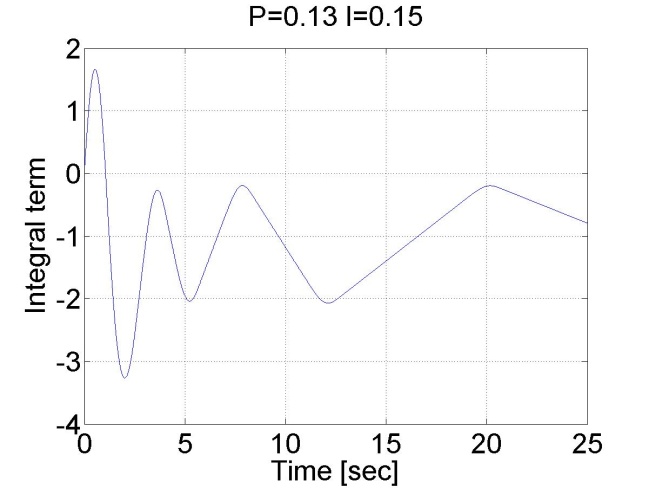

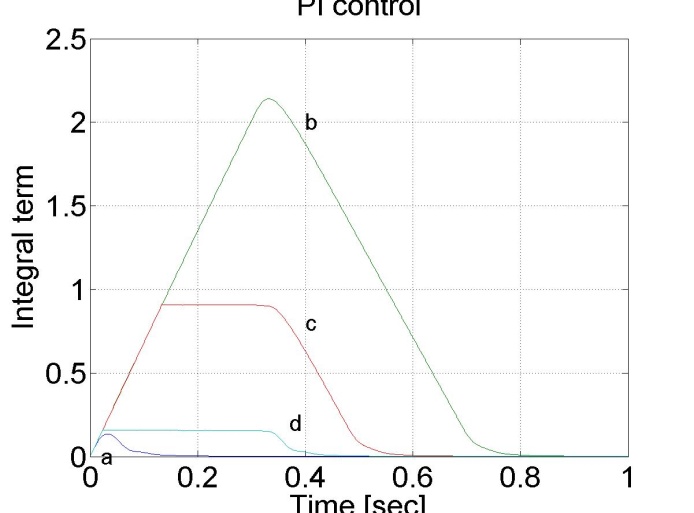

Comparision of the integral terms in two cases

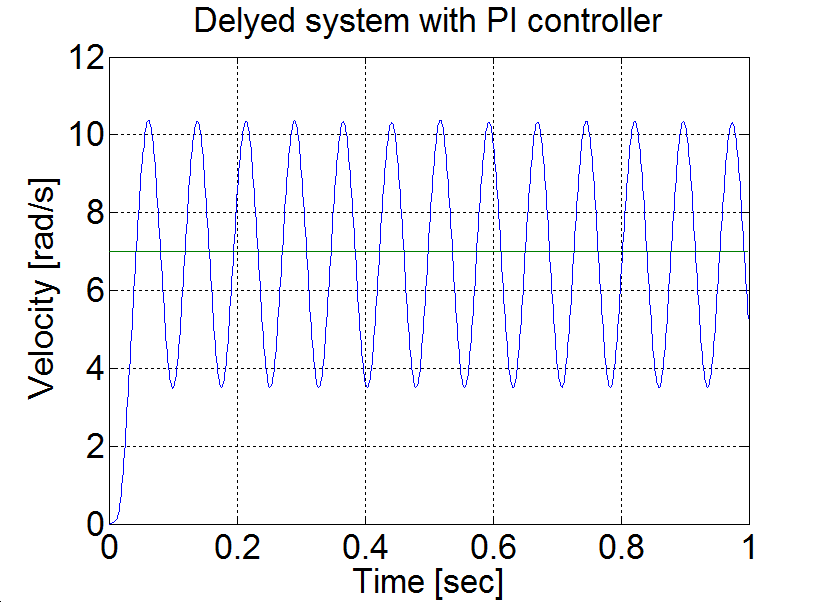

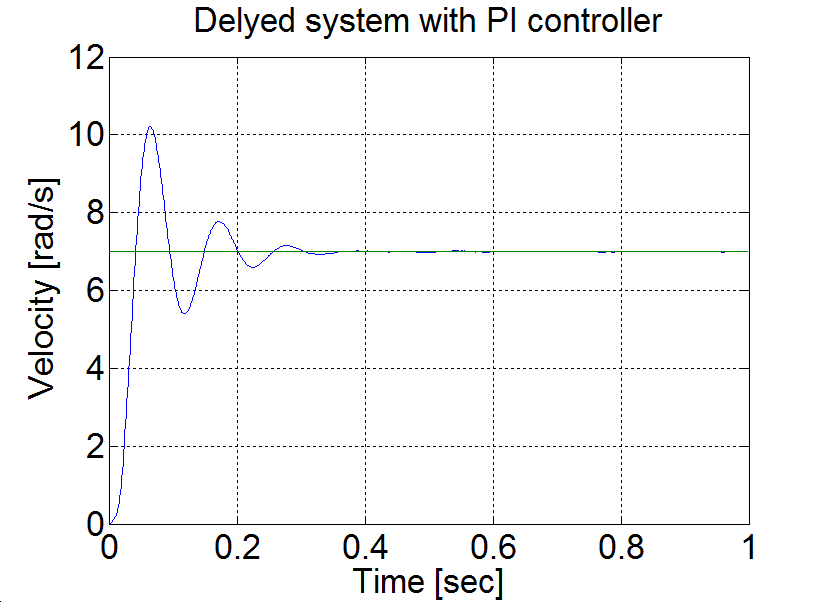

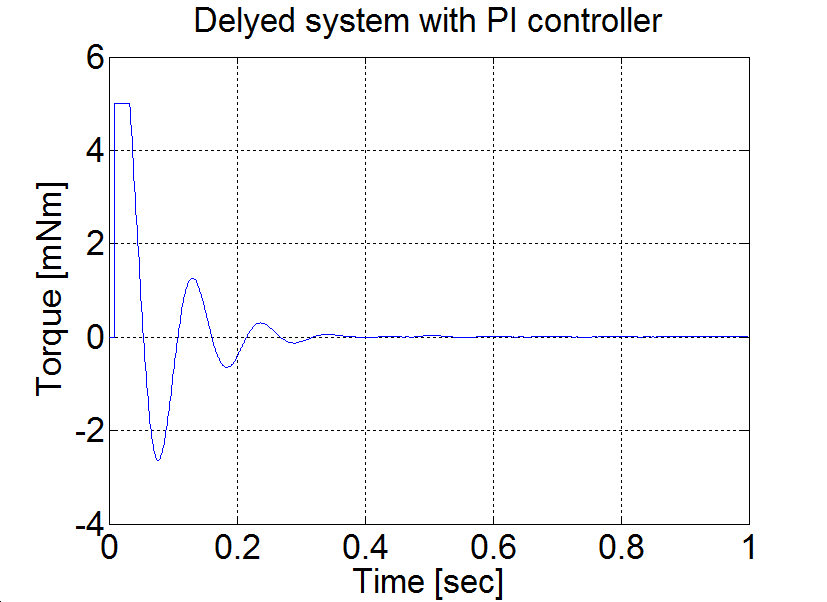

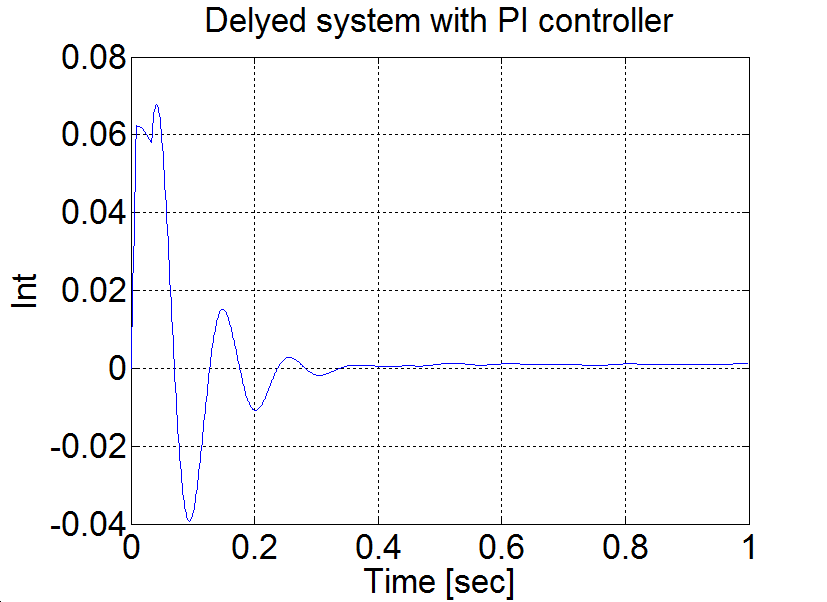

6.5.12. Control of time-delay system

Enter measurement length in milliseconds: 1000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

ref (selected)

-

error (selected)

-

integral (selected)

Declaration:

doubleP_par = 0.85;

doubleI_par = 12.0;

doubleref_vel = 7;

doubleerror_vel;

static doubleerror_vel_int=0.0;

double load = 0;

/* Time delay pipe */

static float T_1=0.0, T_2=0.0, T_3=0.0;

static float T_4=0.0, T_5=0.0, T_6=0.0;

static float T_7=0.0, T_8=0.0, T_9=0.0;

/* velocity filter variables */

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/* Tsample=1e-3 and Tc=0.0032 */

float ad11 = 0.99591, ad12 = 0.00095987, ad13 = 3.652e-007;

float ad21 = -11.3235, ad22 = 0.88778, ad23 = 0.00061567;

float ad31 = -19089.6748, ad32 = -193.6165, ad33 = 0.30752;

float bd1 = 0.0040906, bd2 = 11.3235, bd3 = 19089.6748;

Controller:

//Step changes in reference speed

/* Velocity filter */

ztmp_1=ad11* z_1+ad12* z_2+ad13* z_3 + bd1* ResultData.Velocity;

ztmp_2=ad21* z_1+ad22* z_2+ad23* z_3 + bd2* ResultData.Velocity;

z_3=ad31* z_1+ad32* z_2+ad33* z_3 + bd3* ResultData.Velocity;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

//Error calculation for velocity control

error_vel=ref_vel- ResultData.Velocity;

error_vel_int = error_vel_int + error_vel*(CurrentTime - OldTime)/1000;

ResultData.StateVariable_5 = ref_vel;

ResultData.StateVariable_6 = error_vel;

ResultData.StateVariable_7 = error_vel_int;

ResultData.Torque = T_1;

T_1=T_2;

T_2=T_3;

T_3=T_4;

T_4=T_5;

T_5=T_6;

T_6=T_7;

T_7=T_8;

T_8=T_9;

T_9= P_par*error_vel + I_par*error_vel_int - load;

if (T_9 > 5) { T_9 = 5;

error_vel_int = error_vel_int - error_vel*(CurrentTime - OldTime)/1000;}

if (T_9 < -5) { T_9 = -5;

error_vel_int = error_vel_int - error_vel*(CurrentTime - OldTime)/1000;}

Az eredményeket megjelenítő MATLAB program

% please, modify it according to you file names

sv_1_hwztupv131qjbi55l3k5oi45

sv_2_hwztupv131qjbi55l3k5oi45

sv_3_hwztupv131qjbi55l3k5oi45

sv_4_hwztupv131qjbi55l3k5oi45

sv_5_hwztupv131qjbi55l3k5oi45

sv_6_hwztupv131qjbi55l3k5oi45

sv_7_hwztupv131qjbi55l3k5oi45

time=time/1000;

plot(time,position)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Position [rad]');

title('Delyed system with PI controller');

% you can adjust your axis

axis([0 1 0 12]);

grid

pause;

print -djpeg Delay_poz

plot(time,velocity)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Velocity [rad/s]');

title('Delyed system with PI controller');

% you can adjust your axis

axis([0 1 0 12]);

grid

print -djpeg Delay_vel

pause;

plot(time,torque)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Torque [mNm]');

title('Delyed system with PI controller');

% you can adjust your axis

%axis([0 1 -1 1]);

grid

print -djpeg Delay_torque

pause;

plot(time,int)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Int');

title('Delyed system with PI controller');

% you can adjust your axis

%axis([0 1 -1 1]);

grid

print -djpeg Delay_int

Conclusion AU = 1.7 and TU≈0.08. According to the table PPI=0.85 and IPI=12. Measurement results are shown in Figure 6-7.

P control results

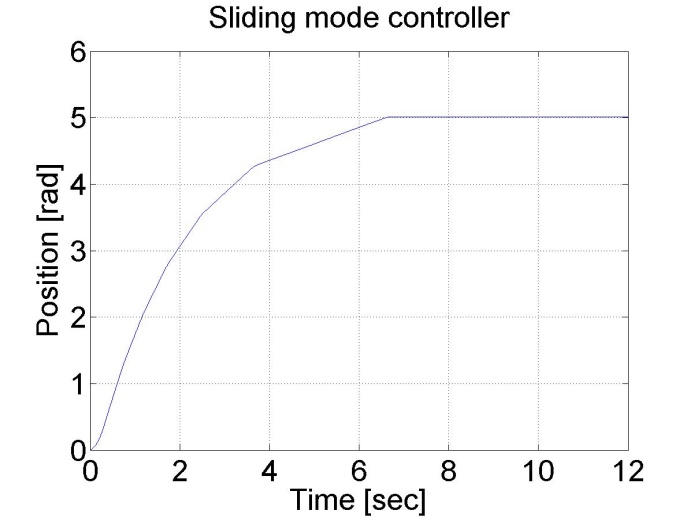

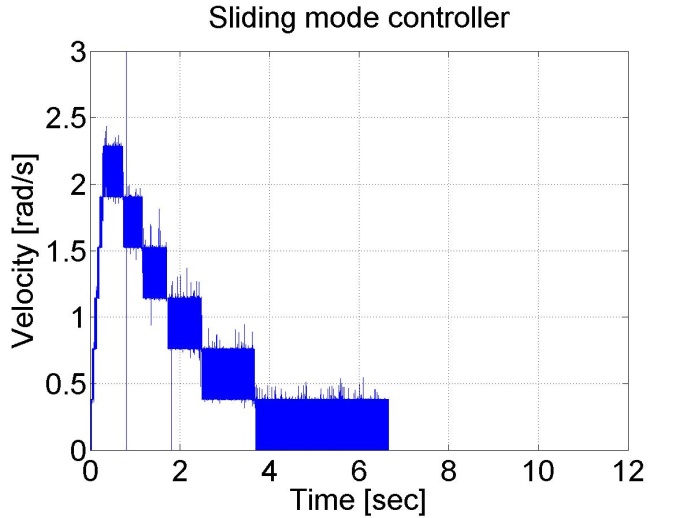

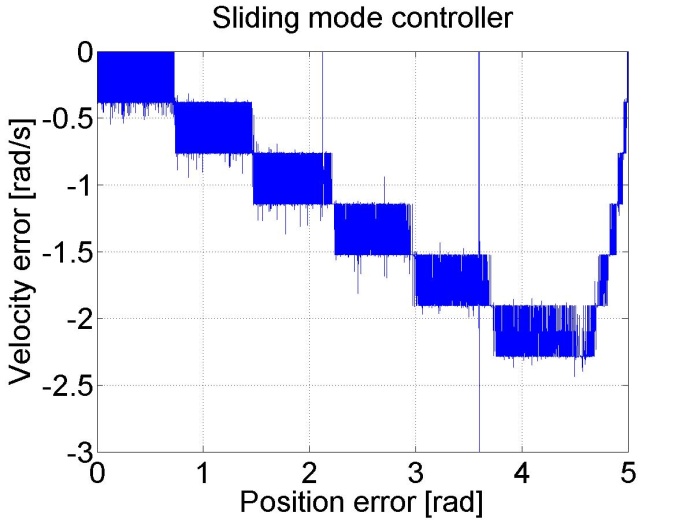

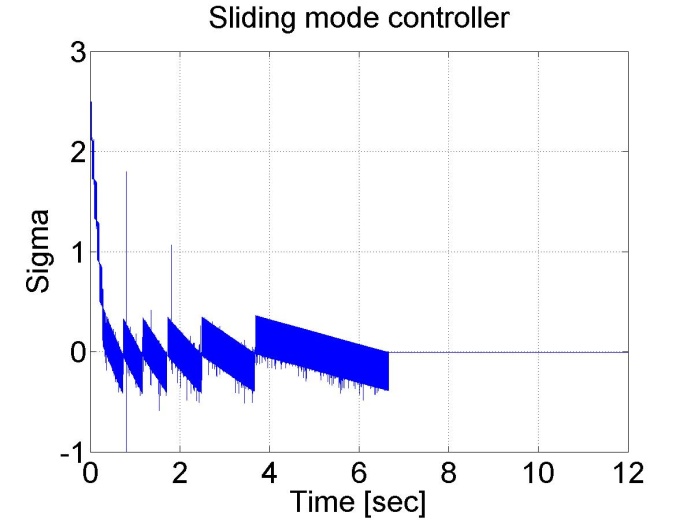

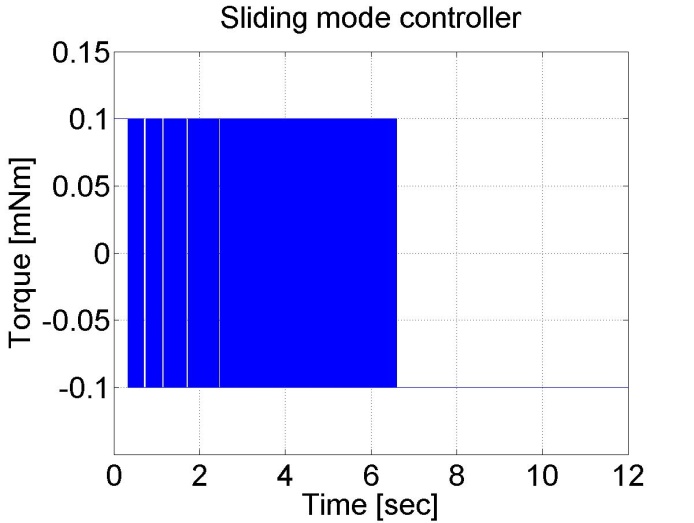

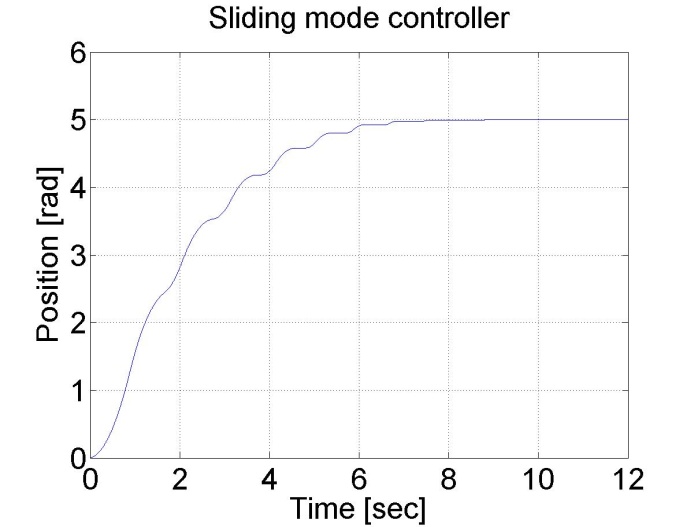

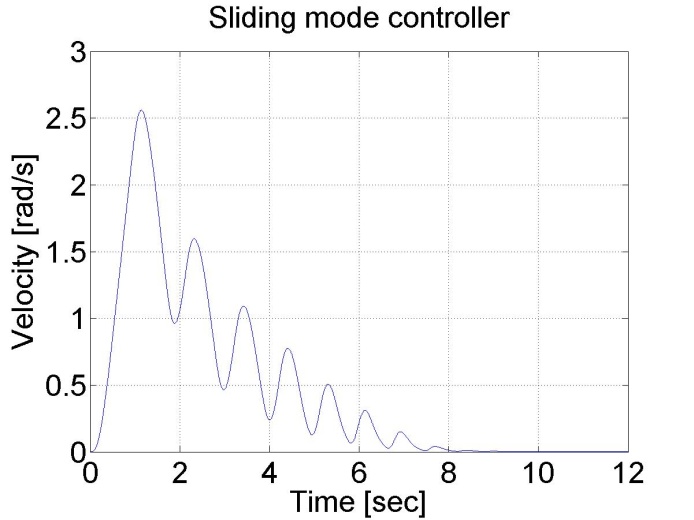

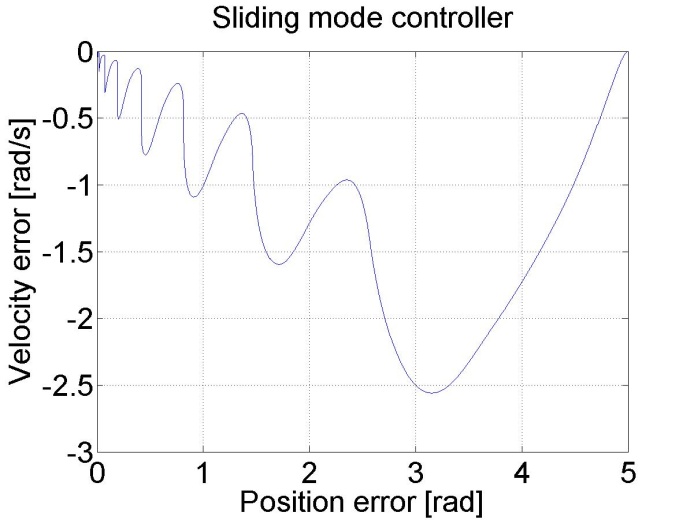

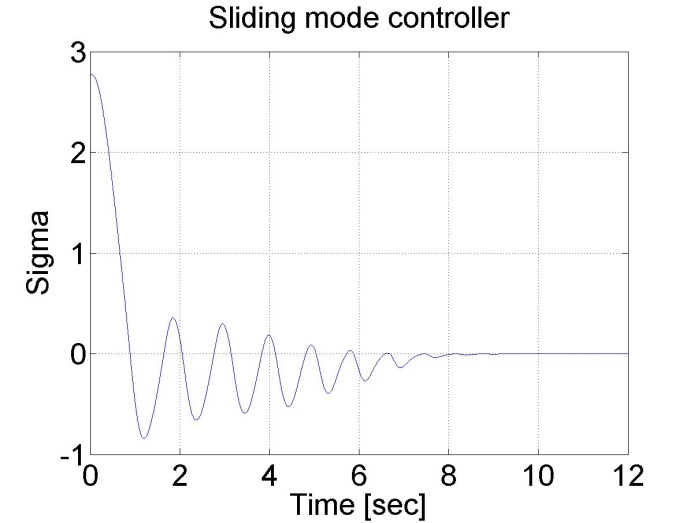

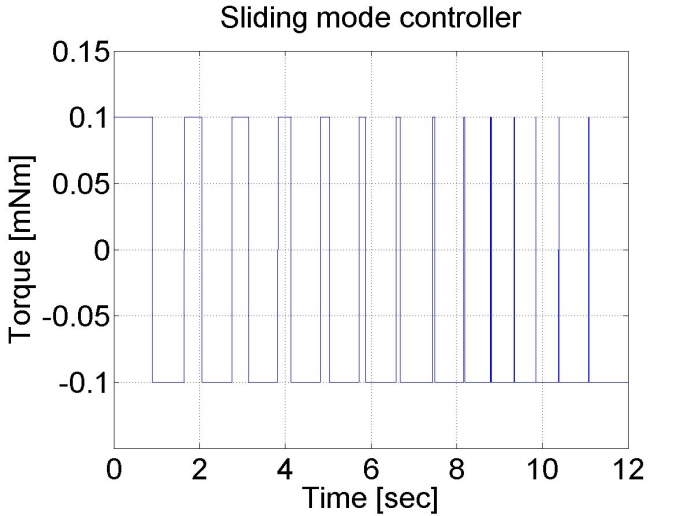

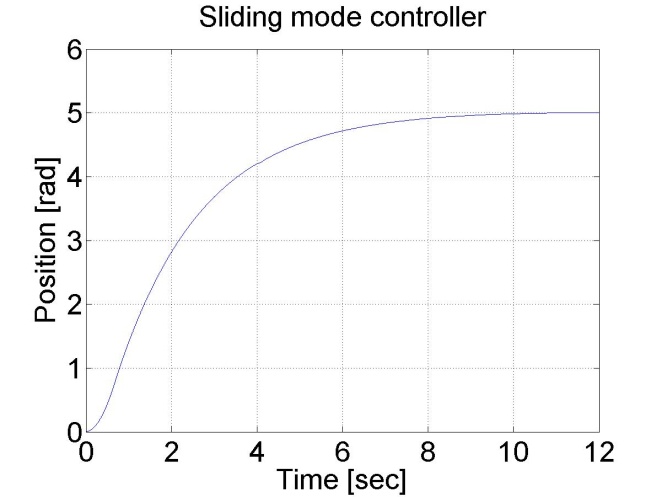

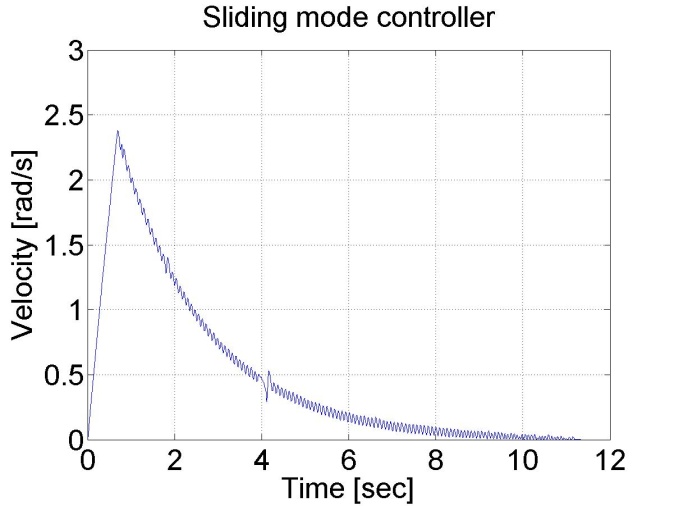

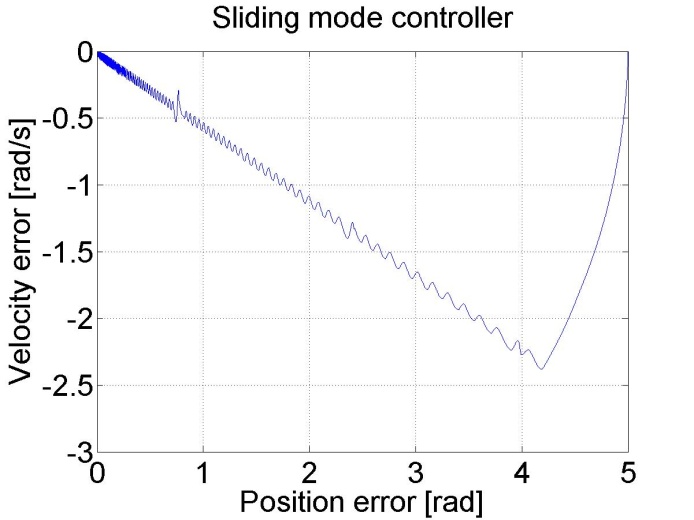

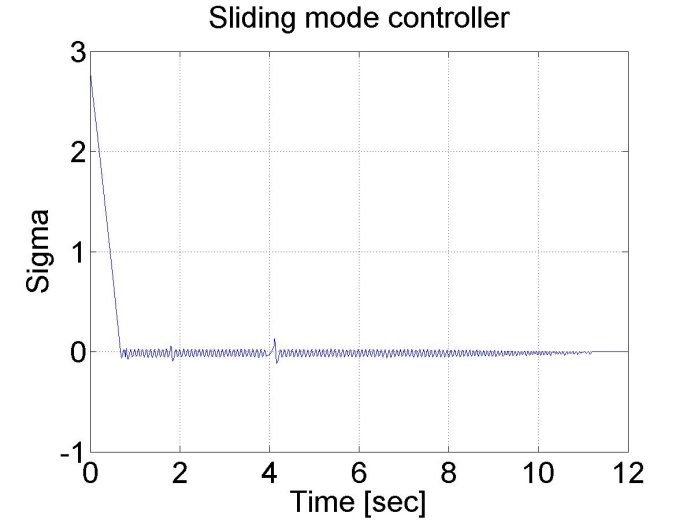

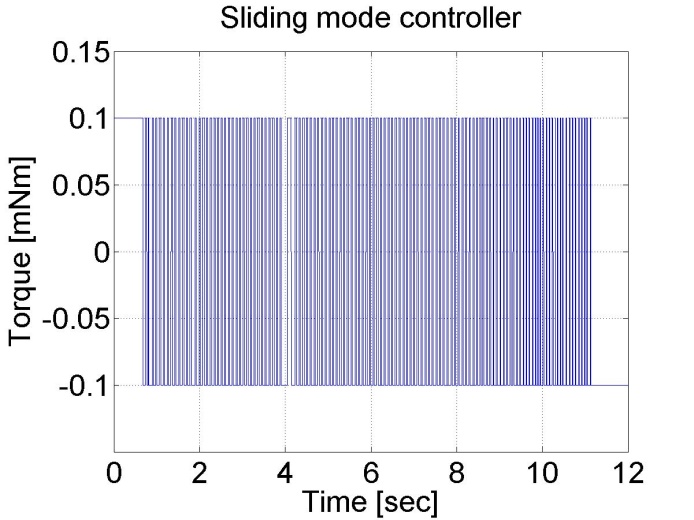

6.5.13. Sliding mode control results

Sliding mode control can be also applied. There are two different measurements. The control part of the measurements is the same, but since the velocity of the motor is calculated from position data, this makes the velocity diagram noisy. By applying a filter for the velocity the results are smoother.

Enter measurement length in milliseconds: 12000

The state variable names:

-

time (given)

-

position (given)

-

velocity (given)

-

torque (given)

-

sigma (selected)

The controller code is the following:

Declaration:

float sigma;

float error;

float error_dot;

float ref=5.0;

float lambda=2;

static double ini_0 = 0;

static double ini_1 = -10;

Controller:

if (ini_1 < 0)

{

ini_0 = ResultData.Position;

}

ini_1 = 5;

error=ref-ResultData.Position+ ini_0;

error_dot=- ResultData.Velocity;

sigma= error+ lambda*error_dot;

ResultData.StateVariable_5 = sigma;

if (sigma>0)

{ ResultData.Torque=0.1;

}

if (sigma<0)

{ ResultData.Torque =-0.1;

}

if (sigma=0)

{ ResultData.Torque=0;

}

Select item to download: All files

Please, download them by clicking the button “DOWNLOAD”

The results are plotted by the following MATLAB file:

% please, modify it according to you file names

sv_1_n0ktqaui51tw5hrtvpypxu45

sv_2_n0ktqaui51tw5hrtvpypxu45

sv_3_n0ktqaui51tw5hrtvpypxu45

sv_4_n0ktqaui51tw5hrtvpypxu45

sv_5_n0ktqaui51tw5hrtvpypxu45

time=time/1000;

plot(time,position)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Position [rad]');

title('Sliding mode controller');

% you can adjust your axis

axis([0 12 0 6]);

grid

pause;

print -djpeg smc_poz

plot(time,velocity)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Velocity [rad/s]');

title('Sliding mode controller');

% you can adjust your axis

axis([0 12 0 3]);

grid

print -djpeg smc_vel

pause;

plot(5-position,-velocity)

set(gca, 'fontsize', [25]);

xlabel('Position error [rad]');

ylabel('Velocity error [rad/s]');

title('Sliding mode controller');

% you can adjust your axis

axis([0 5 -3 0]);

grid

print -djpeg smc_traj

pause;

plot(time,torque)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Torque [mNm]');

title('Sliding mode controller');

% you can adjust your axis

axis([0 12 -0.15 0.15]);

grid

print -djpeg smc_torque

pause;

plot(time,sigma)

set(gca, 'fontsize', [25]);

xlabel('Time [sec]');

ylabel('Sigma');

title('Sliding mode controller');

% you can adjust your axis

axis([0 12 -2.5 2.5]);

grid

print -djpeg smc_sigm

|

|

|

|

|

|

|

|

Figure 6-16. Results of the position controller with sliding mode controller

The sliding mode controller with the velocity filter has the following form:

Declaration:

float sigma;

float error;

float error_dot;

float ref=5.0;

float lambda=2;

/* filter variables*/

static float z_1=0.0, z_2=0.0, z_3=0.0;

static float ztmp_1=0.0, ztmp_2=0.0;

/*omega_c=10 unmodelled dynamics of the filter causes big chattering */

float Azd11= 1, Azd12= 0.0010, Azd13= 0.0000;

float Azd21= -0.0005, Azd22= 0.9999, Azd23= 0.0010;

float Azd31= -0.9851, Azd32= -0.2960, Azd33= 0.9703;

float Bzd1= 0.0000, Bzd2= 0.0005, Bzd3= 0.9851;

/* omega_c= 1/0.007 unmodelled dynamics of the filter does not cause big chattering

float Azd11= 0.9996, Azd12= 9.9072e-004, Azd13= 4.3344e-007;

float Azd21= -1.2637, Azd22= 0.9730, Azd23= 8.0496e-004;

float Azd31= -2.3468e+003, Azd32= -50.5468, Azd33= 0.6280;

float Bzd1= 4.3671e-004, Bzd2= 1.2637, Bzd3= 2.3468e+003;

*/

static double ini_0 = 0;

static double ini_1 = -10;

Controller:

if (ini_1 < 0)

{

ini_0 = ResultData.Position;

}

ini_1 = 5;

error=ref-ResultData.Position+ ini_0;

/* filter */

ztmp_1 = Azd11* z_1 +Azd12* z_2 +Azd13* z_3 + Bzd1*ResultData.Velocity ;

ztmp_2 = Azd21* z_1 +Azd22* z_2 +Azd23* z_3 + Bzd2*ResultData.Velocity ;

z_3 = Azd31*z_1 +Azd32*z_2 +Azd33* z_3 + Bzd3*ResultData.Velocity ;

z_1 = ztmp_1;

z_2 = ztmp_2;

ResultData.Velocity =z_1;

error_dot=- z_1;

sigma=error+ lambda*error_dot;

ResultData.StateVariable_5 = sigma;

if (sigma>0)

{ ResultData.Torque=0.1;}

if (sigma<0)

{ ResultData.Torque =-0.1;

}

if (sigma=0)

{ ResultData.Torque=0;}

The results can be seen in the figure below:

|

|

|

|

|

|

|

|

Figure 6-16. Sliding mode control with a velocity filter

|

|

|

|

|

|

|

|

Figure 6-17. Results of the position controller with sliding mode controller with velocity filter

6.6. Complex design and measurement

In this section the theoretical basics of the DC motor control will be reviewed by focusing on the state feedback control. As the control of the motor is solved by a computer, the model expressed in discretized form. Furthermore the introduced methods will be implemented into MATLAB. In the theoretical review, only the necessary steps for implementation is emphasized. The more detailed description of methods can be found in the recommended literature.

6.6.1. State feedback and its design

Let us consider the following explicit Discrete time invariant state space model:

|

|

(6.1) |

Where

-

: the state vector at k

-

: the column vector of the input signal at k

-

: the vector of the output signal at k,

-

: the system matrix,

-

: the input matrix,

-

: the output matrix,

-

: feedthrough matrix (usually 0),

The purpose of state feedback is to change the system matrix in a way that the behaviour of the system is favourable to us. Since the eigenvalues of are the system’s poles, it is evident, that by changing the eigenvalues we can manipulate the behaviour of the system freely (with particular limits). From the state space equations it can be seen that if we choose to:

|

|

(6.2) |

then the value of can be changed.

Thus we get:

|

|

(6.3) |

Where:

-

: the feedback matrix

-

: the new input signal of the system,

The new system matrix is , which value can be set with . Since K does not affect the system matrix directly - but after the multiplication with – it is not possible to have an arbitrary result.

Hence the condition for design and correct operation of a state feedback is the controllability of the system represented by the state space model. This means that the system can reach any state – with the proper input signal – from any given state in a finite interval. In case of a Discrete time system the condition of total state controllability is that the rank of controllability matrix of the system is equal to the number of state variables (n):

|

|

(6.4) |

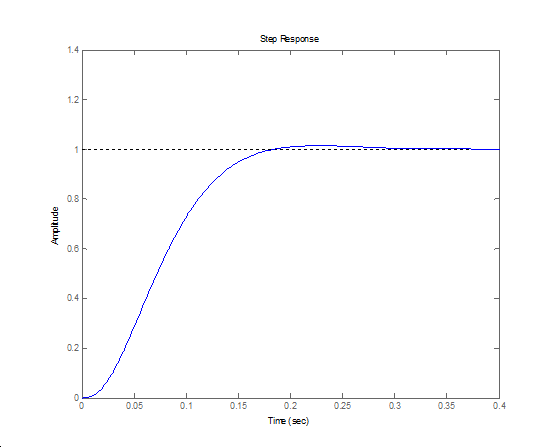

Designing the state feedback is based on constructing the characteristic equation of our own (), where we choose the new placement of the poles. (The number of poles must remain the same of course.). This formula is usually based on the selection of two dominant poles; using these we define the behaviour of the system. Then we choose other auxiliary poles which have higher values than the dominant poles. (The necessity of the auxiliary poles are to keep the number of poles the same.)

Assigning values to the poles happen continuously in case of discrete controllers too, because the controlled plant is usually continuous in time. If we want a stable system, all of the poles must have a negative integer part. We can set the dominant pair of poles with the damping and time constant as well. Let us consider the following oscillating double storage:

|

|

(6.5) |

If , then the poles of the transfer function:

|

|

(6.6) |

Where:

|

|

(6.7) |

|

|

(6.8) |

From the envelope of the unit jump’s response the percentage time constant can be derived:

|

|

(6.9) |

So if the values of and are given, then:

|

|

(6.10) |

From this we can calculate the dominant pair of poles. We choose the further poles much larger, so the effect of these are not significant. If we have the poles in continuous time (), the same can be calculated in Discrete time () with the following formula:

|

|

(6.11) |

where is the sampling period.

The following task is to determine the value of in a way that this can be achieved. In case of Single Input, Single Output (SISO) systems this may be easily reached: All we have to do is compare the system matrix’s poles (parameterized with ) with the chosen poles and calculate . This method is called the Ackermann formula:

|

|

(6.12) |

Where indicates the original system matrix substituted into the desired characteristic equation. In case of Multiple Input, Multiple Output (MIMO) systems determining is a more complex problem and in general only approximate solutions can be achieved; which means the actual values of the poles might be different from the desired ones.

6.6.2. Application of reference signal correction

With the previous procedure we get a system which poles’ are the ones we set. In case of controller design, it is expected that output signal of the whole system in the steady state match the reference signal. For this reason we need the so called reference signal correction. The state feedback controller with reference signal correction has the following structure:

Where is the value of the state vector and is the actuating signal value in steady-state. The feed-forward containing is crucial, because without it, the actuating signal is not in steady-state. (Basically it replaces an integrator.) The component calculates the goal values of the state variables according to the goal values of the output; hence it ensures that the input of is the error signal. It is worthy to note, that in case we use feed-forward alone (without the feedback) the system would eventually reach the end position as well; however not the way we planned.

So the goal is:

|

|

(6.13) |

For this:

|

|

(6.14) |

Determination of :

|

|

(6.15) |

Calculation of :

|

|

(6.16) |

Summarizing:

|

|

(6.17) |

Where is a n x m nullmatrix and is a m x m identity matrix.

6.6.3. Design of the state observer

In real life situations we usually do not have the opportunity to measure all the state variables. It has several reasons; e.g. technically it is not possible to measure the given state variable or it cannot be measured accurately enough, the measurement is not cost efficient or the physical meaning of the state variable is unknown (e.g. in case of artificially created, identification based state space models). In such cases we need a state observer; the general function of the state observer is to determine the state of the system using the input and output signals, which can be easily measured in most cases. Therefore the state observer has two inputs: the block input () and output (); the output of the state observer is the vector of the observed state variables ().

A state observer can only be applied, if the system is observable. Formally, a system is said to be observable if, knowing the inputs and outputs of the system in finite time, the system’s initial state can be determined. In case of time invariant systems in Discrete time it is true when the rank of the system’s observability matrix is maximal, that is its rank is n:

|

|

(6.18) |

The state observer in Discrete time :

|

|

(6.19) |

The estimation error:

|

|

(6.20) |

The goal is to keep the estimation error converging to zero (). Let us substitute the estimation error into the state observer equation and express it:

|

|

(6.21) |

Since:

|

|

(6.22) |

Therefore:

|

|

(6.23) |

It follows that:

|

|

(6.24) |

The last two term is always zero, if:

|

|

(6.25) |

Furthermore our goal is to get as fast as possible. This is valid when the system is stable and fast:

|

|

(6.26) |

It can be ensured by proper selection of . To have this we substitute and in the equation of the estimation error:

|

|

(6.27) |

We transpose the equation:

|

|

(6.28) |

Let us compare this with the state feedback equation:

|

|

(6.29) |

It is visible, that the two equations are very similar and we can use that to determine the value of , using the methods applied in case of state feedback. Consider the following system:

|

|

(6.30) |

If we design a state feedback for this system, the value of is:

|

|

(6.31) |

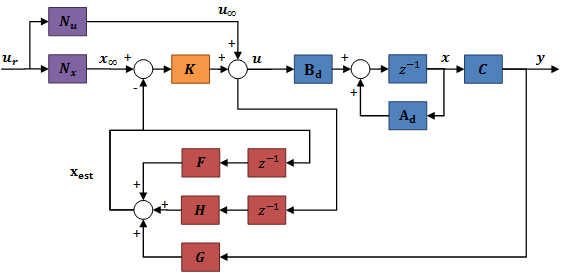

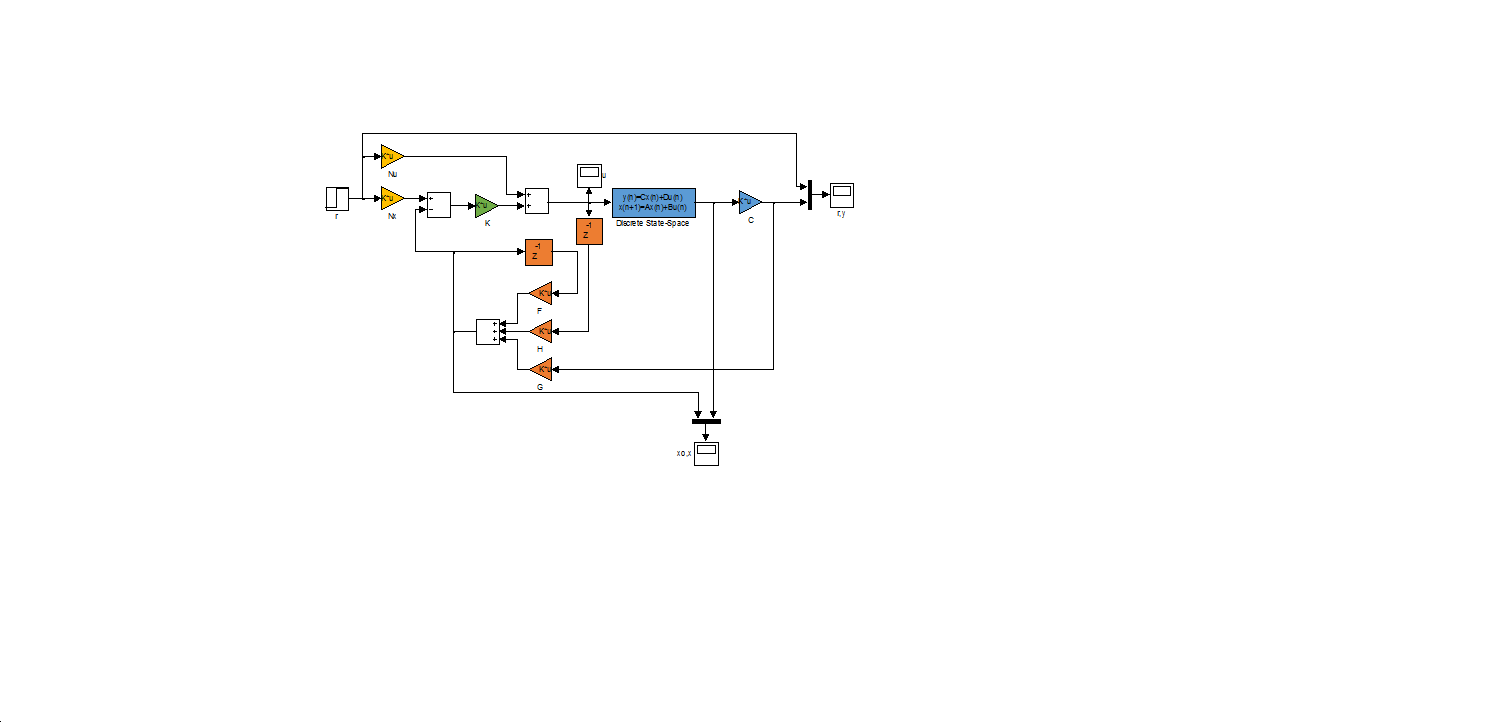

The only important remaining issue is the pole placement. To decide this matter we should use the greatest absolute valued pole in continuous time (obtained in the primary state feedback design) and choose many orders of magnitude larger. Selecting it carefully plays a crucial role in the stability of the system, especially if the actual system is different from the model, because the slow observer causes an unstable system. Therefore it is a basic requirement for a state observer that it must operate faster than the observed system. With this we get the following controller:

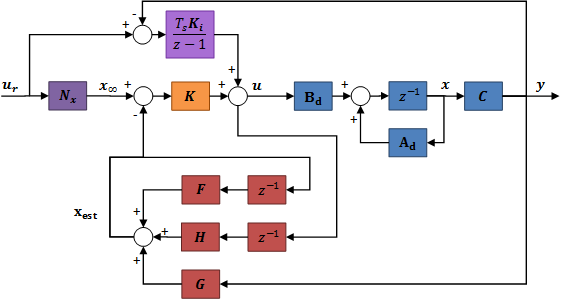

6.6.4. Integral control

Up to this point the designed controller works great theoretically: we decide the pole placement of the system, we determine how and how fast the system should reach steady state; and there is no steady-state error. What if the block is different from the one we used during design? In this case the state feedback will not place the poles to their designed location, since they are not in the place where we expect them to be; this may even lead to an unstable system and certainly lead to steady-state error, because the reference signal correction is based on the state space equations. On top of that, the state observer would not observe the real states.

The solution for the steady-state error is placing an integrator into the system. Using this we can eliminate the part of the reference signal correction, since the integrator also has an output in case there is no error. In order to build in the integrator, introducing a new state variable is necessary:

|

|

(6.32) |

Here the Discrete time integrator is based on the left hand endpoint method. Extending the block state space equations with this:

|

|

(6.33) |

The state feedback have the following form:

|

|

(6.34) |

Thus in this case we design the state feedback to this extended system and we use the obtained and matrices as follows:

As we can see, the feed-forward containing is replaced with the integrator, since the integrator ensures the lack of steady-state error. Placing the integrator in the feed-forward does not affect the design of the reference signal correction and the state observer.

6.6.5. Identification of the system

First we need to determine the model of the controller before the designing process can begin. To do that, we use the MATLAB System Identification Toolbox. The toolbox gives the possibility to identify systems from measurement results, which can be used for controller design. An important condition for this is to have a measurement which represents the system properly; since the program creates the system using the input and output values, any special phenomenon that does not occur in the measurement (but in the real system) is likely to not occur in the model as well. Before we start the measurement, it is practical to select the model we would use. In this case designing the controller would require a state space model in Discrete time . This can be easily derived from a transfer function. MATLAB offers several options to do that, we are going to use the ARMAX model. ARMAX is an acronym; it stands for AutoRegressive Moving-Average model with eXogenous inputs. A question regarding the emphasis of exogenous input may occur; hence before presenting the ARMAX model, we should understand two of its components, the AR and MA models. The AutoRegressive (AR) model:

|

|

(6.35) |

Where:

-

is the output value at time step

-

is the internal input, white noise value at time step

-

As we can see, this is a stochastic process. The Moving-Average (MA) has the same structure:

|

|

(6.36) |

Where. Since these models have no exogenous inputs, they are not suitable for describing the engine; however putting the models together and extending it with exogenous inputs we obtain the so called ARMAX model, which is eligible. The formula of the ARMAX model:

|

|

(6.37) |

Where:

-

is the exogenous input

-

is the system delay

-

, here the first coefficient is not 1. The reason for this is to have an arbitrary amplification of the system.

The purpose of the term containing the white noise input is to map the measurement error. Actually this is the error of the equation:

|

|

(6.38) |

If there is no measurement error, then :

|

|

(6.39) |

Therefore the transfer function:

|

|

(6.40) |

MATLAB can construct the transfer function for us, however understanding the basic operational principles may be useful. Substituting the values as parameters into the ARMAX equation, the magnitude of the error is given as a function of the polynomials coefficient. The value of the polynomials and thus the transfer function can be determined by minimizing the square of the error. The MATLAB does not determine the value of the delay time; it has to be given by the user.

From the transfer function we can develop a state space model in more than one way, e.g. observable canonical form, controllable canonical form, etc. In this methods, the physical meaning of the state variables are unknown; however this is not a disadvantage, since we do not expect this behaviour because of identification. In most cases the state space representation can be derived from the transfer function as follows:

|

|

(6.41) |

Let:

|

|

(6.42) |

With this:

|

|

(6.43) |

Consider the state variables as follows:

|

|

(6.44) |

Hence:

|

|

(6.45) |

The state space model:

|

|

(6.46) |

In possession of the state space model, the controller design may be performed.

6.6.6. Design of the control

After the review of the theoretical basics the design of the control can be done in the following three steps:

Identification of the system

-

Design and simulation of the control

-

Implementation and analysis of the control

These will be introduced in this section.

6.6.7. Identification of the motor

6.6.7.1. Analysis of the characteristics

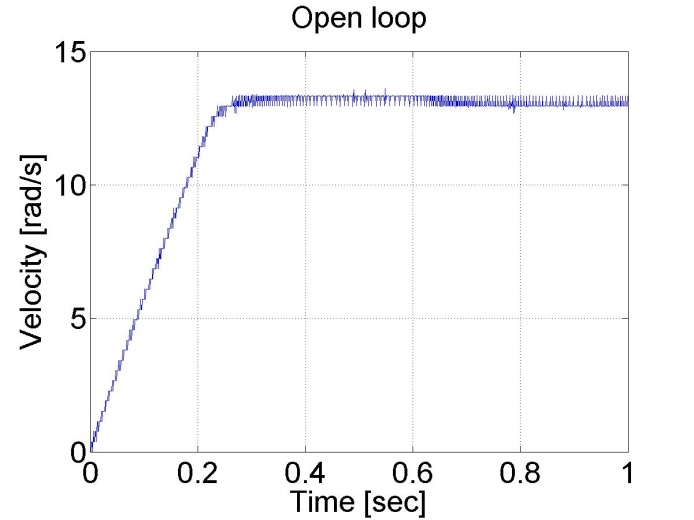

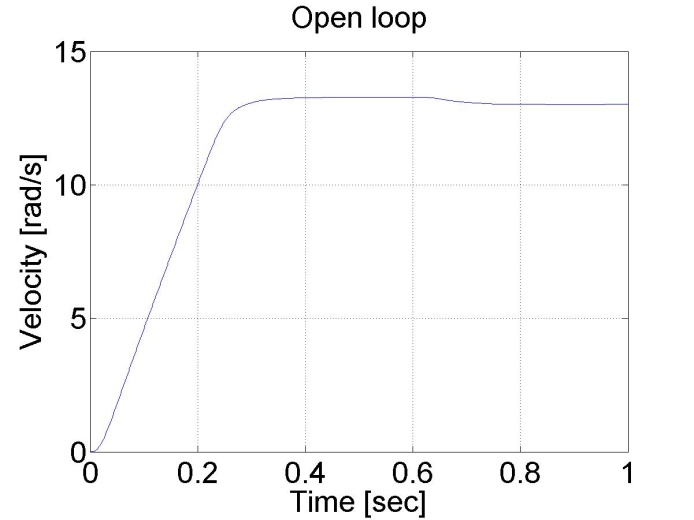

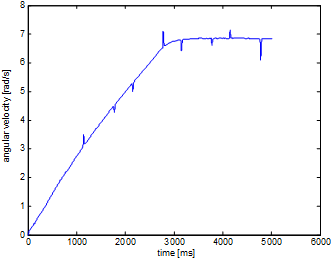

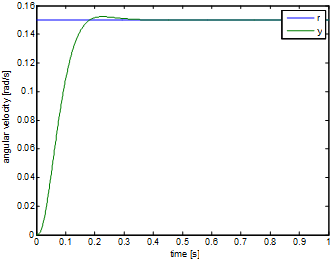

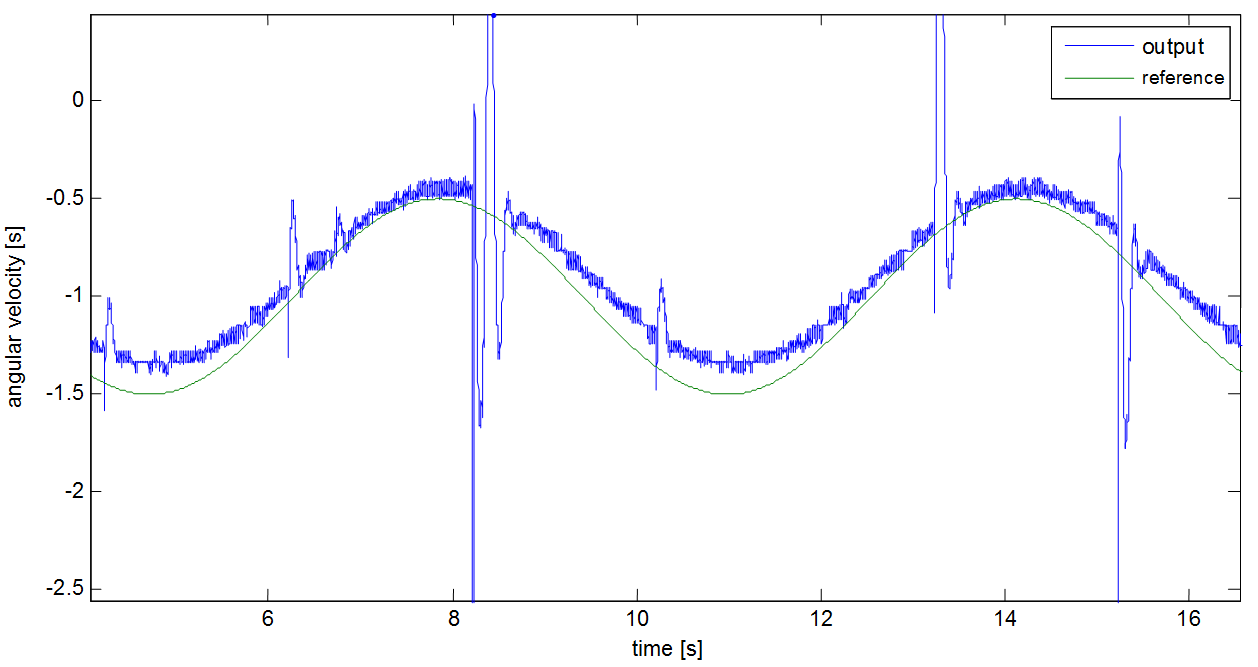

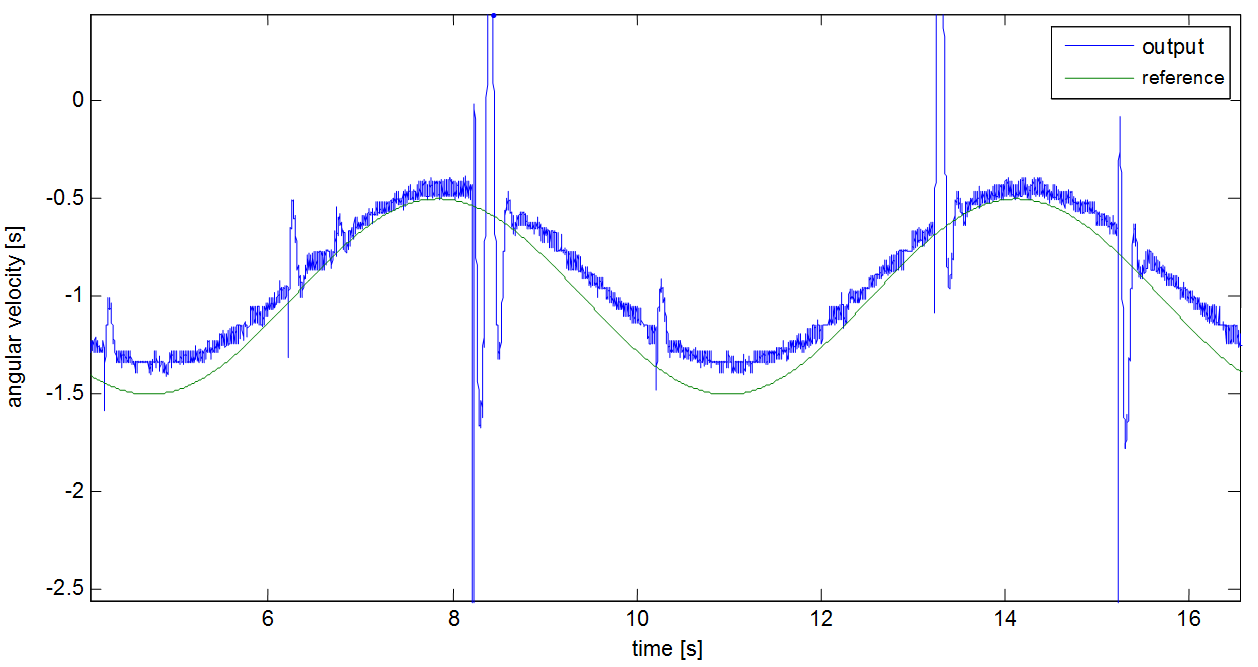

First the system had to be analysed. The DC motor available via the internet. With the help of the working system, the control of the input signals can be written in C programming language. By sending the C code to the remote monitoring station, it will be compiled and the result will be sent back. In this case the input of the motor is the required moment. From this moment, the current controller computes the output voltage. Thus the damaging input signals are prohibited. While the controlled output is the velocity of the motor. The maximal achievable angular velocity in the case of constant input signal (100 mNm):

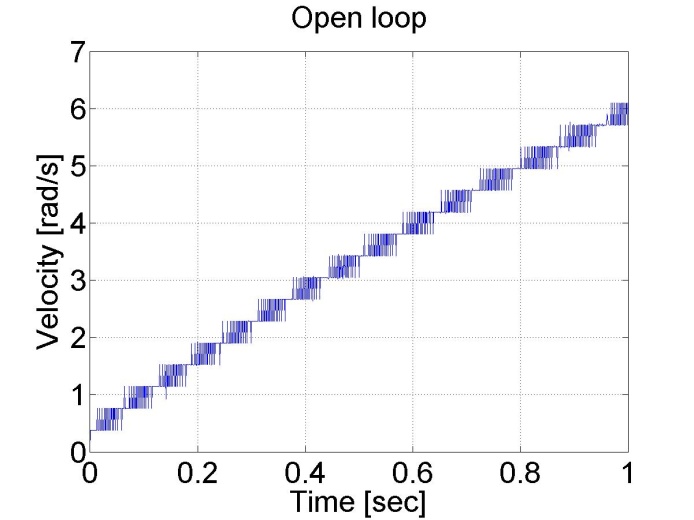

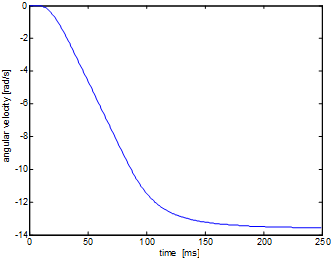

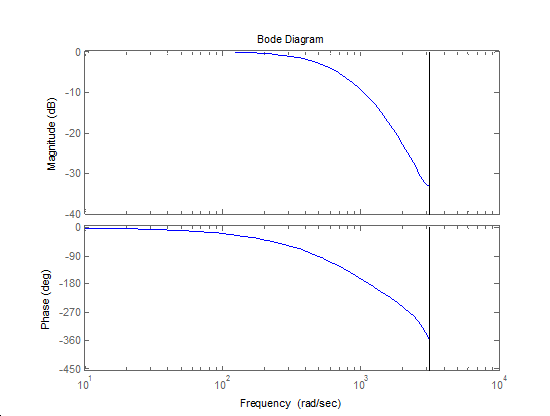

It can be noticed that the velocity is computed from the position by numerical differentiation and filtering. Therefore some pike still remain in the result. The designing of the filter will be detailed in later section.

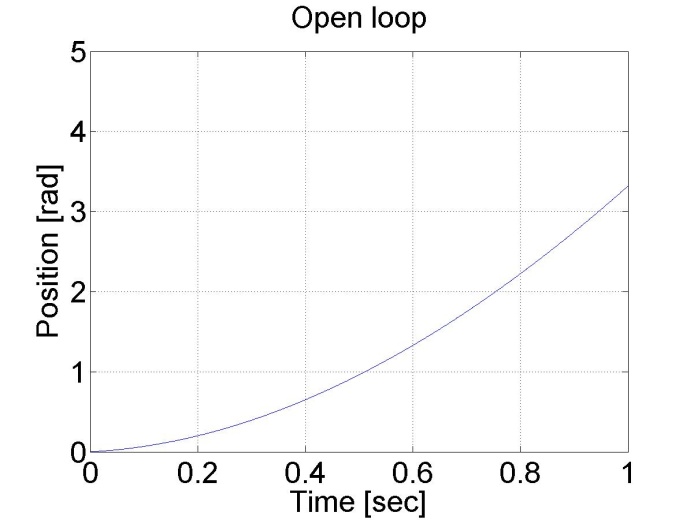

In the case of 3 mNm :

After more measurement, it can be stated that the maximum of the angular valocity is 14 rad/s. Furthermore it can be seen that the system gives higher response in the case of less moment. This means that the current control works wrong in the case of high input moments.

In the case of inversed direction of rotation (-3 mNm):

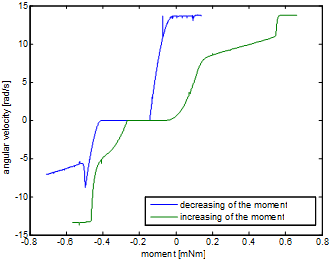

It can be seen that the absolute value of the extremes are about the same as in the previous case. In the next step, the system will be analysed by a quasi-static measurement to obtain the relation between the input moment and the output velocity. The measurement begin with a -3 mNm as an input and it increased slowly until +3 mNm:

The figure above shows that the characteristic of the system is far away from linear:

-

Deadband: because of static friction.

-

There are more breakpoint.

-

Hysteresis: The direction of the moment change is also an important factor.

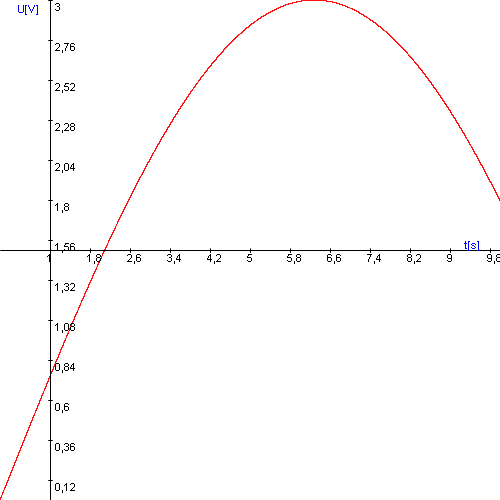

6.6.7.2. Design of the excitation for the identification

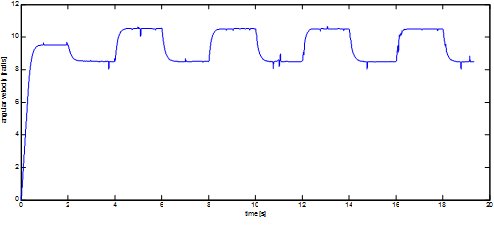

To achieve a well working control, the system has to be as linear as possible. Even the case of non linear system, every system can be linearized around a given working point. Thus, to demonstrate the operating of the control, a precision velocity controller will be made. At first the system is taken into the close area of the working point then the system pass to the precision control.

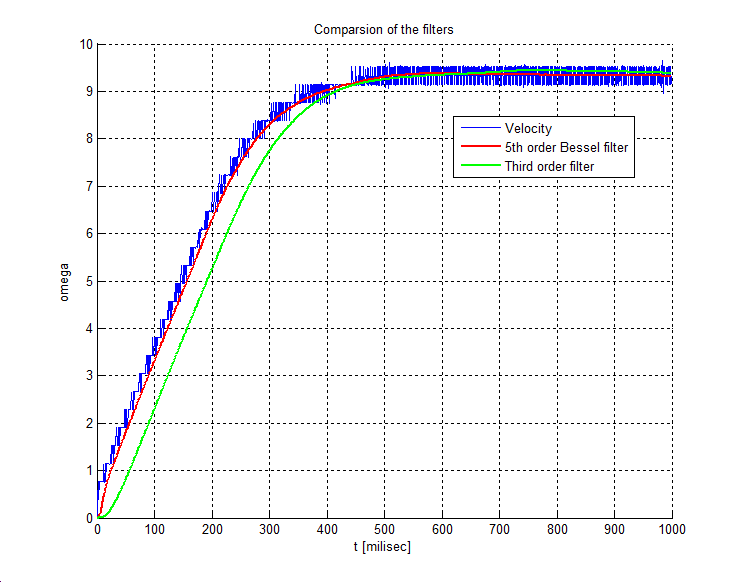

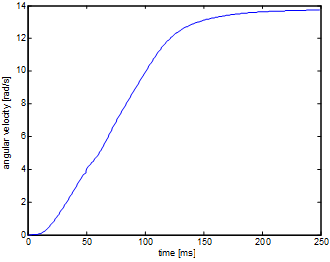

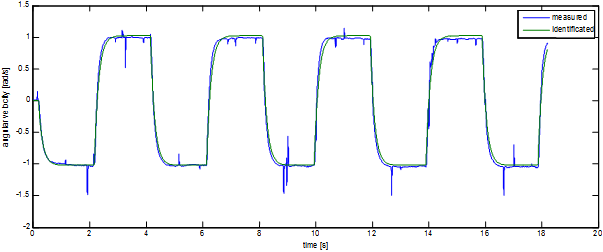

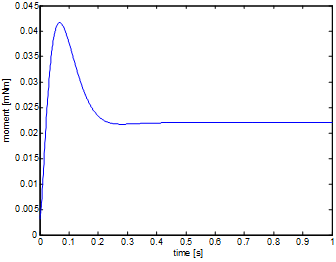

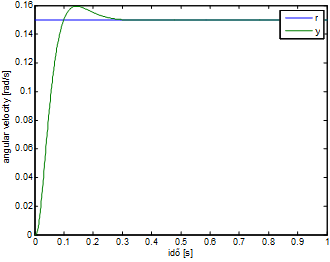

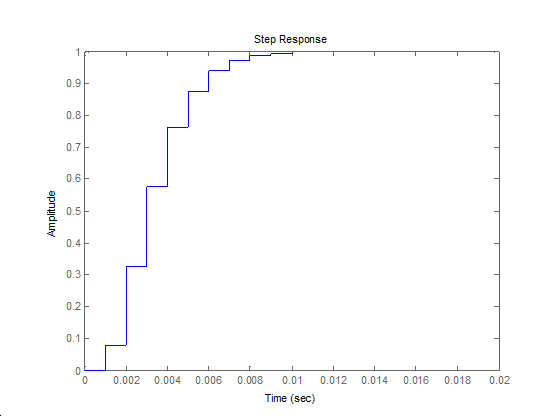

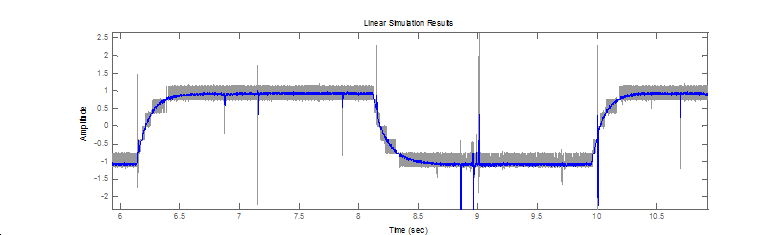

After the system is taken into the close area of the working point, a square wave signal is applied as input. The response of the system will be the basics of the identification. Then the picked linear section should be the linear section between 0.2mNm and 0.5mNm. For the identification of this, a square wave signal is used by setting of 4s as the time of period, 0.35mNm as the mid-torque and 0.15 as the amplitude. And 2 seconds was given to reach the working point:

The 6-15.figure shows the output of the system. And this output well approximates the output of a linear system. The C code of the measurement is:

typedef struct

{

float Position;

float Velocity;

float Torque;

float StateVariable_5;

float StateVariable_6;

float StateVariable_7;

float StateVariable_8;

float StateVariable_9;

float StateVariable_10;

NewControllerData

NewControllerData CalculateController(

const float CurrentPosition,

const float OldPosition,

const float OldVelocity,

const float CurrentTime,

const float OldTime,

const float Old_StateVariable_5,

const float Old_StateVariable_6,

const float Old_StateVariable_7,

const float Old_StateVariable_8,

const float Old_StateVariable_9,

const float Old_StateVariable_10

NewControllerData ResultData; // result

//Filter coefficient

static float filB0 = 0, filB1 = 0.00013337, filB2 = 0.0012028, filB3 = 0.0009847099, filB4 = 7.3193E-05;

static float filA0 = 1, filA1 = -3.1152, filA2 = 3.6392, filA3 = -1.8895, filA4 = 0.36788;

//input

static float input0 = 0, input1 = 0, input2 = 0, input3 = 0, input4 = 0;

//filtered value

static float filter0 = 0, filter1 = 0, filter2 = 0, filter3 = 0, filter4 = 0;

float u;

//mid-value of the moment

float bias = 0.35;

//waiting for the set up

int start = 2000;

//time of the period

int period = 4000;

//amplitude

float amplitude = 0.15;

// Position is saved automatically

ResultData.Position = CurrentPosition;

// angular velocity is saved automatically

if (CurrentTime != 0.0f){

ResultData.Velocity = (1000.0f * (float)(CurrentPosition - OldPosition)/(float)(CurrentTime - OldTime));

}

else {

ResultData.Velocity = 0.0f;

}

//velocity filtering

input0 = ResultData.Velocity;

filter0 = (filB0 * input0 + filB1 * input1 + filB2 * input2 + filB3 * input3 + filB4 * input4 - (filA1 * filter1 + filA2 * filter2 + filA3 * filter3 + filA4 * filter4)) / filA0;

input4 = input3; input3 = input2; input2 = input1; input1 = input0;

filter4 = filter3; filter3 = filter2; filter2 = filter1; filter1 = filter0;

ResultData.StateVariable_5 = filter0;

//the moment

if(CurrentTime < start)

{

u = 0;

}

else

{

u = (((int)CurrentTime - start) % period - period / 2 > 0 ? amplitude : -amplitude);

}

ResultData.Torque = u + bias;

ResultData.StateVariable_6 = u;

return ResultData;

}

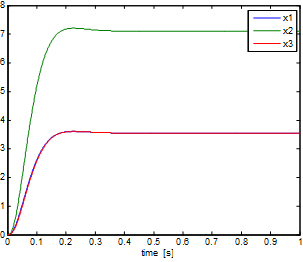

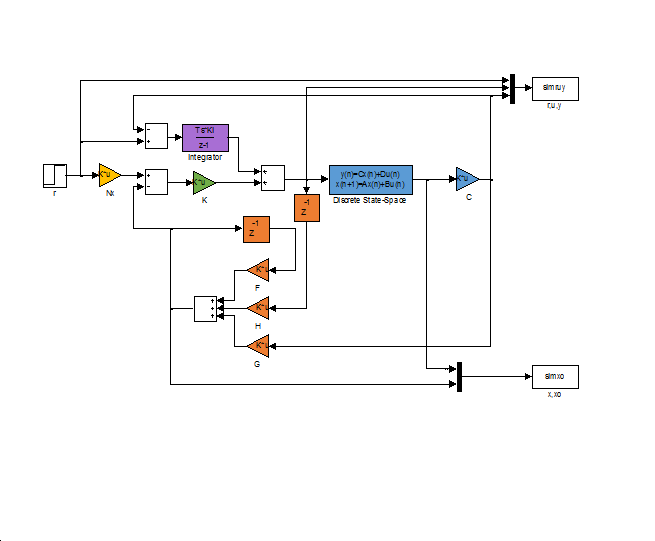

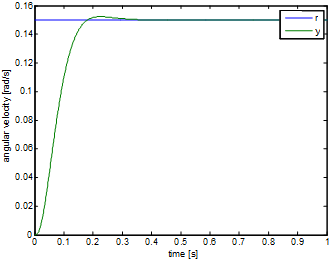

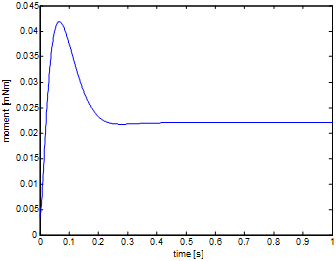

6.6.7.3. Identification with the help of the MATLAB